Đăng nhập

Liên hệ

Description

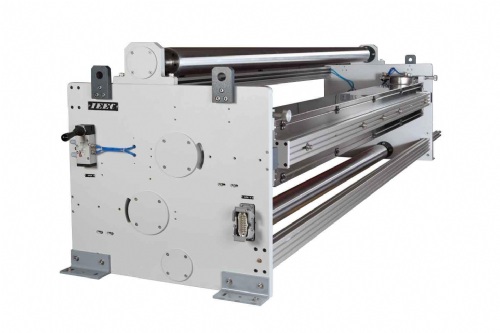

The process of increasing Surface Tension (dynes/cm) of a substrate by exposing it to an Atmospheric Plasma Flame is called Atmospheric Plasma Treatment. Non-contaminated, refrigerated dry, moisture free, and oil-free compressed air is passed through High Voltage at High Frequency. Air molecules get ionized and air reaches fourth stage of matter (Plasma), creating Atmospheric Plasma.

Principle

This treatment works on a simple principle that the Ion and the electron mixed in the Plasma Zone run against each other in High Speed on the surface of the material. This eliminates foreign matter (dust etc.) and helps the functional coating radical to stick on the surface. This process helps achieve a rinsing effect and Hydrophilic effect on the surface – resulting in increased Surface Tension.

Technology

The advanced technology of atmospheric plasma is accurate and accepted worldwide. A Plasma Flame is generated by using compressed natural air instead of other gases, making it an economical

Principle

This treatment works on a simple principle that the Ion and the electron mixed in the Plasma Zone run against each other in High Speed on the surface of the material. This eliminates foreign matter (dust etc.) and helps the functional coating radical to stick on the surface. This process helps achieve a rinsing effect and Hydrophilic effect on the surface – resulting in increased Surface Tension.

Technology

The advanced technology of atmospheric plasma is accurate and accepted worldwide. A Plasma Flame is generated by using compressed natural air instead of other gases, making it an economical

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry