Login

Contact

Description

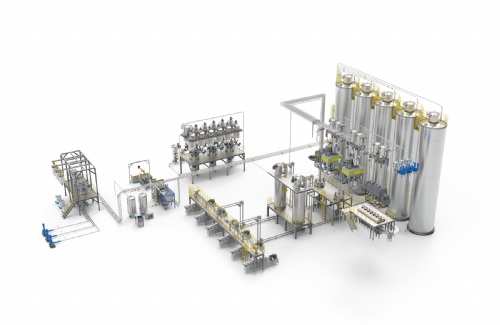

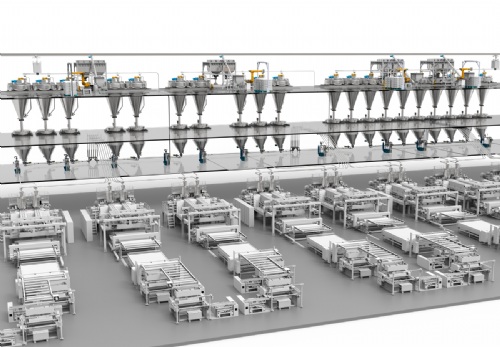

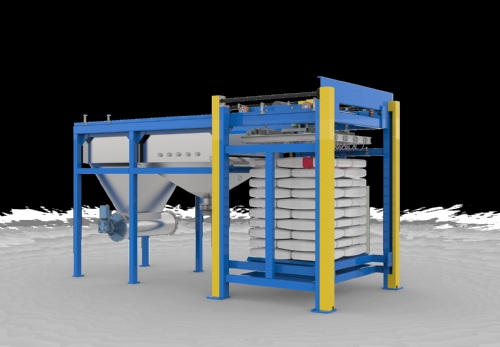

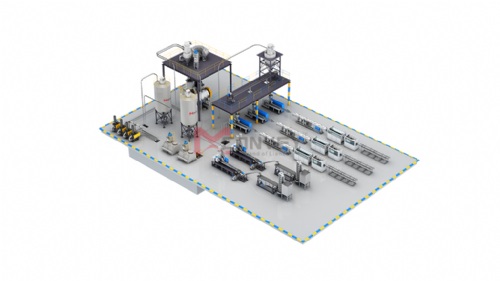

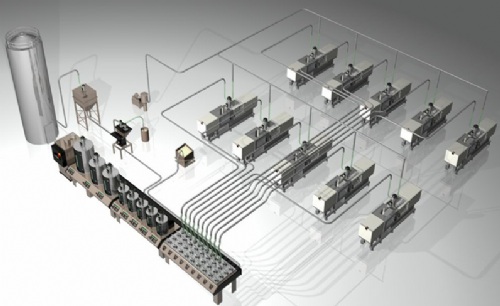

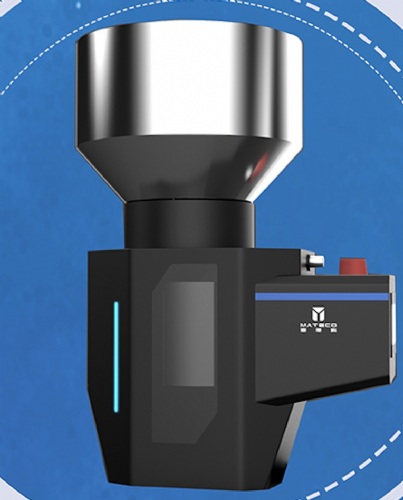

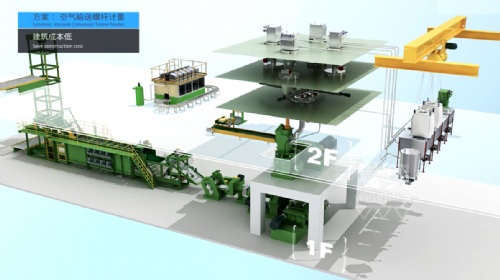

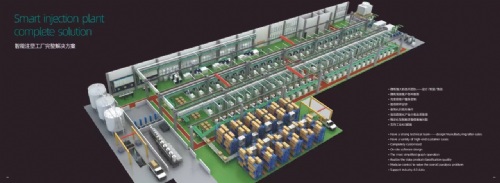

A blending and homogenization system is an industrial equipment used for mixing different materials to achieve a uniform distribution, widely used in industries such as cement, chemical, and building materials. Here are some characteristics of blending and homogenization systems:

1.?Uniform Mixing: The system ensures that different components of materials are thoroughly mixed to meet product quality requirements.

2.?High Efficiency: The blending and homogenization system is designed for rapid mixing, reducing the mixing time and improving production efficiency.

3.?Automated Control: The system is typically equipped with an automated control system for automatic adjustment and monitoring of the mixing process.

4.?Flexibility: It can adjust mixing ratios and times according to different production needs, adapting to variable production conditions.

5.?Reduction of Dead Zones: The design minimizes dead zones in the mixing process to ensure thorough mixing of materials.

6.?Ease of Operation and Maintenance: The user interface is friendly, operations are simple, and maintenance is convenient, reducing the training time for operators.

7.?Durability: Made with wear-resistant materials and structural design to extend the service life of the equipment.

8.?Reduction of Environmental Pollution: Enclosed or semi-enclosed designs reduce dust dispersion during the mixing process, lowering the environmental impact.

9.?Improved Material Utilization: Precise control of mixing ratios reduces material waste and improves material utilization rates.

10.?Data Recording and Analysis: The system can record data during the mixing process for subsequent data analysis and quality control.

11.?Strong Adaptability: Capable of adapting to different material characteristics and mixing requirements, including varying viscosities, densities, and particle sizes.

12.?Safety: The system design considers operational safety, equipped with necessary safety protection measures.

13.?Scalability: The capacity and functionality of the system can be conveniently expanded according to the scale of production.

14.?Energy Saving: Energy efficiency was considered in the design, reducing energy consumption.

Blending and homogenization systems, with these characteristics, provide businesses with an efficient, reliable, and environmentally friendly material mixing solution, helping to improve product quality and production efficiency.

1.?Uniform Mixing: The system ensures that different components of materials are thoroughly mixed to meet product quality requirements.

2.?High Efficiency: The blending and homogenization system is designed for rapid mixing, reducing the mixing time and improving production efficiency.

3.?Automated Control: The system is typically equipped with an automated control system for automatic adjustment and monitoring of the mixing process.

4.?Flexibility: It can adjust mixing ratios and times according to different production needs, adapting to variable production conditions.

5.?Reduction of Dead Zones: The design minimizes dead zones in the mixing process to ensure thorough mixing of materials.

6.?Ease of Operation and Maintenance: The user interface is friendly, operations are simple, and maintenance is convenient, reducing the training time for operators.

7.?Durability: Made with wear-resistant materials and structural design to extend the service life of the equipment.

8.?Reduction of Environmental Pollution: Enclosed or semi-enclosed designs reduce dust dispersion during the mixing process, lowering the environmental impact.

9.?Improved Material Utilization: Precise control of mixing ratios reduces material waste and improves material utilization rates.

10.?Data Recording and Analysis: The system can record data during the mixing process for subsequent data analysis and quality control.

11.?Strong Adaptability: Capable of adapting to different material characteristics and mixing requirements, including varying viscosities, densities, and particle sizes.

12.?Safety: The system design considers operational safety, equipped with necessary safety protection measures.

13.?Scalability: The capacity and functionality of the system can be conveniently expanded according to the scale of production.

14.?Energy Saving: Energy efficiency was considered in the design, reducing energy consumption.

Blending and homogenization systems, with these characteristics, provide businesses with an efficient, reliable, and environmentally friendly material mixing solution, helping to improve product quality and production efficiency.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry