Exhibitor Profile

JIN-ENERGY SAVING TECHNOLOGY CO., LTD

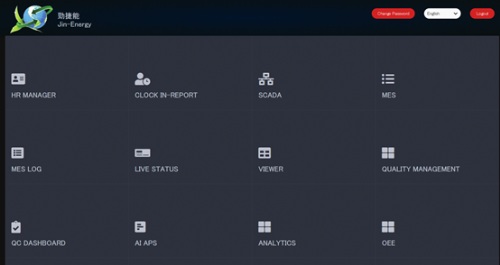

Industrial Internet of Things (IoT) Systems – Smart Factory Management In the era of smart manufacturing, data is the new competitive edge. Jin Energy Saving Technology offers a fully integrated Industrial IoT Smart Factory Management System, helping manufacturers achieve complete digital transformation. Our AI Smart Scheduling System (APS) generates optimal production plans based on orders, capacity, and resources. The Manufacturing Data Management System (MMS) consolidates equipment, mold, material, and process data for real-time decision-making, while the MES + SCADA system enables live monitoring, work order tracking, and production line visualization. The platform also includes workforce and performance management with time tracking and efficiency reports, a Quality Control (QC) module to enhance inspections and product consistency, real-time dashboards for progress and alerts, automated equipment maintenance scheduling to maximize uptime, and advanced analytics to identify bottlenecks and drive continuous improvement. Through seamless integration, intelligent monitoring, and data-driven insights, Jin Energy Saving Technology empowers enterprises to build efficient, sustainable, and future-ready smart manufacturing environments.

• Area:

Plastic

• Booth No:

A130

• Website:

https://www.jin-energy.com.tw/

You may also like

Highest Rated Exhibitors

CONG TY TNHH MAY MOC CHINH XAC YIZUMI (VIET NAM)

HUAYUAN (VIETNAM) MACHINERY COMPANY LTD.

JIANGSU QINGCHENXING TECHNOLOGY CO., LTD

THUAN LOI PLASTIC CO., LTD.

SHANGHAI CMIC MACHINERY AND ELECTRICAL PRODUCTS CO., LTD.

FU CHUN SHIN MACHINERY MANUFACTURE CO., LTD.

JWELL MACHINERY (HAINING) CO., LTD.

HIEP HOI NHUA VIET NAM (VPA)

CONG TY TNHH CONG NGHE VAT LIEU MOI YONG YING

APEX MATERIAL INDUSTRIAL VINA CO., LTD

SHINI PLASTICS TECHNOLOGIES, INC.

TTGH TECH COMPANY LIMITED

SAKAI CHEMICAL (VIET NAM) CO., LTD

PAN STONE PRECISION INDUSTRIES CO., LTD.

KIN JOIN CO., LTD.

ETANA INDUSTRIAL CO., LTD.

ALBIS VIETNAM LIMITED

GUAN SHENG POLYMER TECHNOLOGY COMPANY LIMITED

OMEGA PLASTO LIMITED.

TAN HUNG CO MANUFACTURING AND TRADING COMPANY LIMITED

CHEMICAL TRADING VIETNAM CO., LTD

PACIFIC INTERCHEM CORPORATION

CONG TY CO PHAN CUNG UNG NGUYEN LIEU DONG BAC

PLASCOM CO., LTD

KUAN HSIN CHEMICALS ENT. CO., LTD.

DYNACHEM CO., LTD.

SYNCRO ASIA CO., LTD

HOTAI INDUSTRIAL CO., LTD.

JUNYAN CO., LTD

CONG TY CP TAN SEIKO

Back

Exhibitor Inquiry

Exhibitor Inquiry