Đăng nhập

Liên hệ

Description

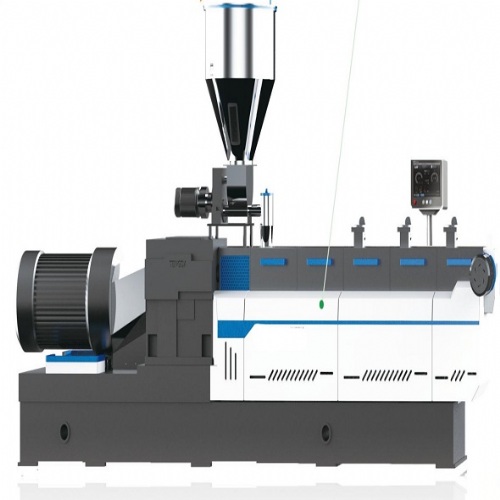

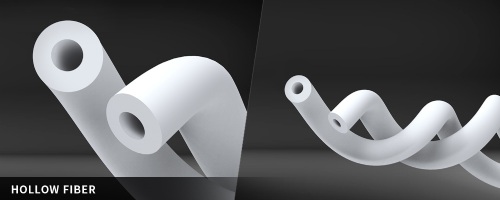

At BKS you are assured of a professional grinding service for your strand pelletizing equipment. We re-sharpen your cutting rotors and rotor cutting machines according to OEM prescription (MAAG, RIETER, AUTOMATIK, SCHEER, IPS, COPERION, PELL-TEC, ACCRAPAK, DREHER, MECCANOPLASTICA, PREVIERO, CUMBERLAND, CONAIR, BPM, LABTECH etc.)

We work with optical identification and control to track your expensive cutting tools.

Execution of the rotor grinding process assures correct full profile grinding for the best lifetime. As we keep track of your cutting rotors in our database, it enables us to advise optimization of rotor cutting material, profile and finish.

We work with Swiss made Schneeberger 5-axis CNC machines to ensure consistent, repetitive quality with minimal diameter reduction.

We can Supply of new cutting rotors/ Bed knives in any material (Tool Steel, Stainless, Powder Metal, Stellite and Carbide) and spare parts for your Pelletizing machine (feedrollers/wipers/bed knife holders)

We work with optical identification and control to track your expensive cutting tools.

Execution of the rotor grinding process assures correct full profile grinding for the best lifetime. As we keep track of your cutting rotors in our database, it enables us to advise optimization of rotor cutting material, profile and finish.

We work with Swiss made Schneeberger 5-axis CNC machines to ensure consistent, repetitive quality with minimal diameter reduction.

We can Supply of new cutting rotors/ Bed knives in any material (Tool Steel, Stainless, Powder Metal, Stellite and Carbide) and spare parts for your Pelletizing machine (feedrollers/wipers/bed knife holders)

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry