Đăng nhập

Liên hệ

Description

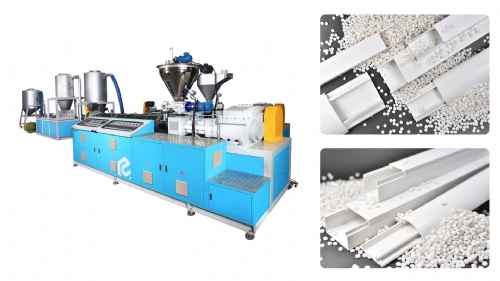

The in mold labeling process combines the operation of labeling with the injection molding process, eliminating the need for labeling or printing processes after plastic products are formed, solving the printing problems of multiple faces, irregular surfaces, and multi-colors. At the same time, it effectively avoids chemical pollution of the product cavity caused by later printing, shortens the production cycle of injection molded products, and reduces production costs. The labeling process within injection molds has been developed for many years and has been widely used in various products. Plastic furniture products such as various buckets, plates, bowls, tea cups, ice cream, trash cans, stationery, tables, chairs, drawers, etc.

With the increasing improvement of people's quality of life, in mold labeling technology will be more widely applied.

With the increasing improvement of people's quality of life, in mold labeling technology will be more widely applied.

Related Products

Highest Rated Products

Back

Product Inquiry

Product Inquiry