Đăng nhập

Liên hệ

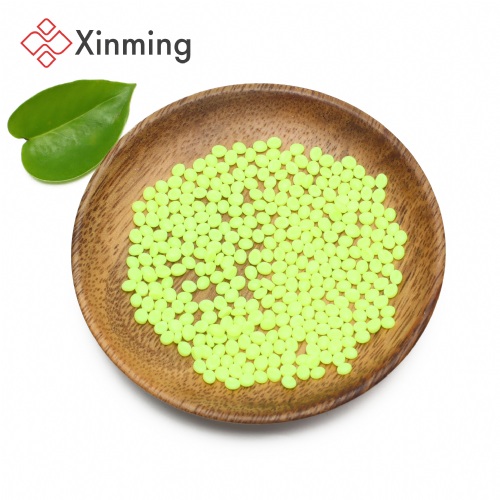

Description

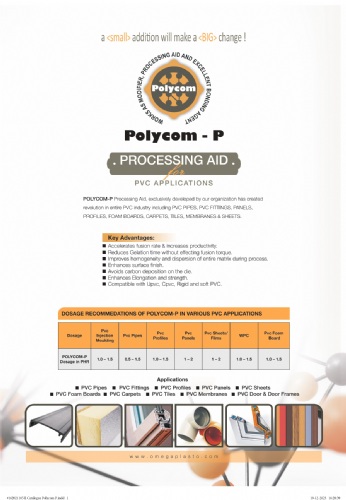

Why use PPA:

PPA widens the operating parameters window and allow more control in product quality and consistencies.

General concept on polymer processing:

The lower the processing temperature, the better for mechanical properties.

The shorter heat transition within Extruder, the better for plastic properties to retain original specification.

Applications:

PPA can be used in materials as follows,

Polyolefins, such as PE, PP, XLPE, PPR, PEX, POE etc.

PPA can be used in improving the performance of resins for the following types of manufacturing methods,

Blow Film

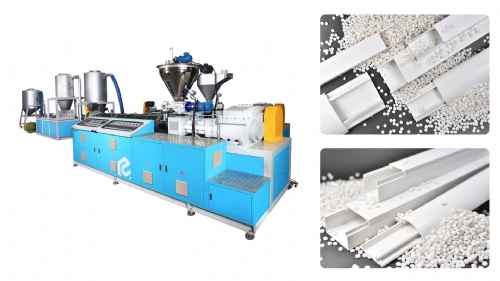

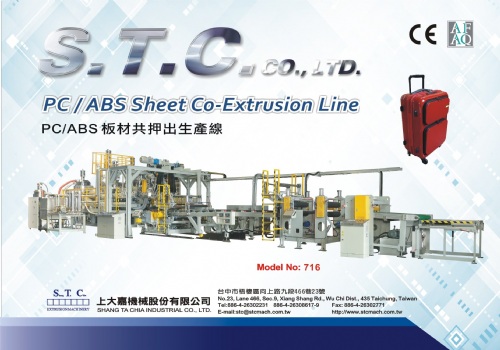

Pipe/Profile Extrusion

Fiber Spinning

Injection Molding

Casting

Yarn/Filament Extrusion

PPA widens the operating parameters window and allow more control in product quality and consistencies.

General concept on polymer processing:

The lower the processing temperature, the better for mechanical properties.

The shorter heat transition within Extruder, the better for plastic properties to retain original specification.

Applications:

PPA can be used in materials as follows,

Polyolefins, such as PE, PP, XLPE, PPR, PEX, POE etc.

PPA can be used in improving the performance of resins for the following types of manufacturing methods,

Blow Film

Pipe/Profile Extrusion

Fiber Spinning

Injection Molding

Casting

Yarn/Filament Extrusion

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry