Đăng nhập

Liên hệ

Description

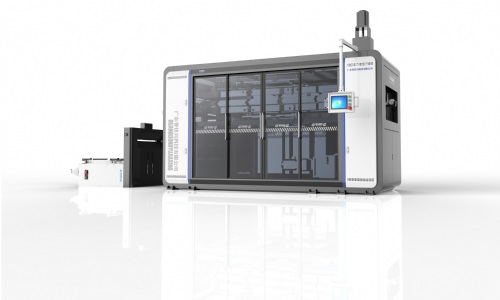

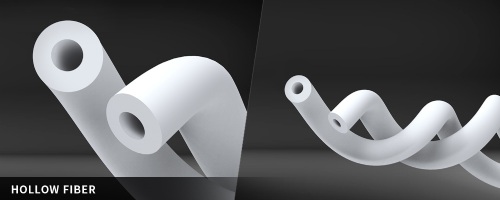

It consists of cooling water supply, pipelines, and a large condenser. By utilizing the principle of water vapor exchange, a gas-liquid exchange mode is formed between the hot steam hydrate and the liquid after entering the central vacuum condenser through the main pipeline. At the same time, through multiple partitions and layout optimization, the gas temperature is reduced to below 40 degrees Celsius after being exchanged according to the set method, thereby achieving efficient condensation.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry