Đăng nhập

Liên hệ

Description

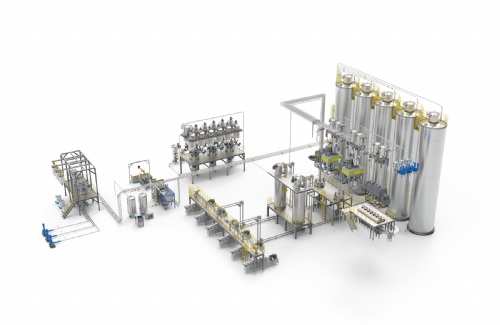

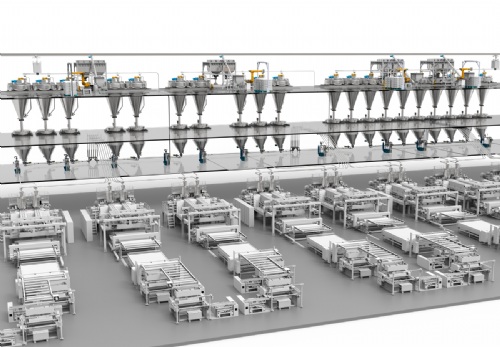

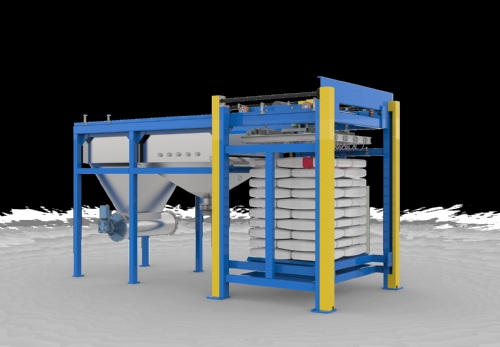

An automatic packaging system is a high-efficiency automated equipment used to package products into their final form for sale or transportation. Here are some characteristics of an automatic packaging system:

1.?High Efficiency: Automated operations significantly increase packaging speed and production volume.

2.?Labor Reduction: Reduces reliance on manual labor, lowering labor costs.

3.?Precise Control: The system can precisely control packaging dimensions, weights, and sealing quality.

4.?Flexibility: Adapts to packaging needs for products of different shapes, sizes, and types.

5.?Ease of Operation: User-friendly interfaces simplify the setup and operation processes.

6.?Error Reduction: Minimizes human errors, improving the consistency and accuracy of packaging.

7.?Enhanced Product Protection: Ensures products are properly protected during the packaging process to reduce damage.

8.?Easy Integration: Can be easily integrated into existing production lines, working in concert with other manufacturing equipment.

9.?Data Recording: Records relevant data during the packaging process for quality control and traceability.

10.?Material Waste Reduction: Reduces waste by using packaging materials precisely.

11.?Brand Image Enhancement: Standardized and professional packaging elevates the market image of the product.

12.?Safety: Equipped with safety measures to ensure the safety of operators and equipment.

13.?Scalability: Capable of expanding system functions and capacity according to changes in production needs.

14.?Strong Adaptability: Adapts to different packaging materials, such as plastic film, paper boxes, and cardboard boxes.

15.?Easy Maintenance: Designed with convenience in maintenance to reduce downtime.

Automatic packaging systems, with these features, provide businesses with a reliable, efficient, and economical packaging solution that helps to enhance production efficiency and product quality.

1.?High Efficiency: Automated operations significantly increase packaging speed and production volume.

2.?Labor Reduction: Reduces reliance on manual labor, lowering labor costs.

3.?Precise Control: The system can precisely control packaging dimensions, weights, and sealing quality.

4.?Flexibility: Adapts to packaging needs for products of different shapes, sizes, and types.

5.?Ease of Operation: User-friendly interfaces simplify the setup and operation processes.

6.?Error Reduction: Minimizes human errors, improving the consistency and accuracy of packaging.

7.?Enhanced Product Protection: Ensures products are properly protected during the packaging process to reduce damage.

8.?Easy Integration: Can be easily integrated into existing production lines, working in concert with other manufacturing equipment.

9.?Data Recording: Records relevant data during the packaging process for quality control and traceability.

10.?Material Waste Reduction: Reduces waste by using packaging materials precisely.

11.?Brand Image Enhancement: Standardized and professional packaging elevates the market image of the product.

12.?Safety: Equipped with safety measures to ensure the safety of operators and equipment.

13.?Scalability: Capable of expanding system functions and capacity according to changes in production needs.

14.?Strong Adaptability: Adapts to different packaging materials, such as plastic film, paper boxes, and cardboard boxes.

15.?Easy Maintenance: Designed with convenience in maintenance to reduce downtime.

Automatic packaging systems, with these features, provide businesses with a reliable, efficient, and economical packaging solution that helps to enhance production efficiency and product quality.

Highest Rated Products

Back

Product Inquiry

Product Inquiry