Đăng nhập

Liên hệ

Description

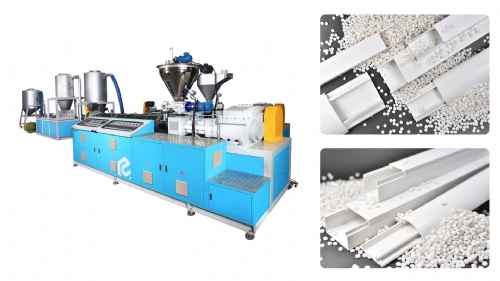

EPS block moulding is defined as a process manufacturing blocks for insulation material or civil engineering applications.

Space between foaming beads is maintained approximately 40% even if the beads fully fill a moulding machine. Heating the beads with steam makes the beads be foamed again The evaporation of volatile material in the beads causes the volumetric expansion, eliminating space between beads. This thermally fuses the beads to each other to produce blocks with shapes identical to the space in the moulding machine.

Block moulds are made in various size with different cavity volume as per customer different requirement .

Main Features :

1. High strength frame of block moulding machine; keep more safety test pressure

2. Al Plate with Teflon Coating or stainless steel for block Chamber

3. Less de-form & accurate machining process keep non-leakage instead of changing sealing frequently

4. All gauges , solenoid valve are used world brand’s ones for double safety

5. Mitsubishi PLC, Schneider touch screen for easy operation

6. Automatic working process

7. Energy-saving system

Space between foaming beads is maintained approximately 40% even if the beads fully fill a moulding machine. Heating the beads with steam makes the beads be foamed again The evaporation of volatile material in the beads causes the volumetric expansion, eliminating space between beads. This thermally fuses the beads to each other to produce blocks with shapes identical to the space in the moulding machine.

Block moulds are made in various size with different cavity volume as per customer different requirement .

Main Features :

1. High strength frame of block moulding machine; keep more safety test pressure

2. Al Plate with Teflon Coating or stainless steel for block Chamber

3. Less de-form & accurate machining process keep non-leakage instead of changing sealing frequently

4. All gauges , solenoid valve are used world brand’s ones for double safety

5. Mitsubishi PLC, Schneider touch screen for easy operation

6. Automatic working process

7. Energy-saving system

Highest Rated Products

Back

Product Inquiry

Product Inquiry