Đăng nhập

Liên hệ

Description

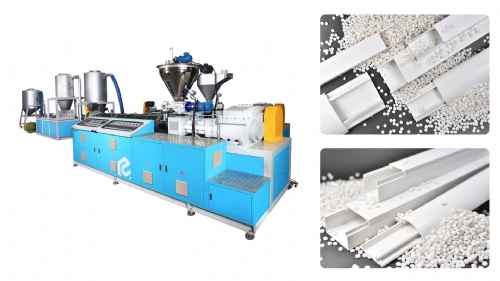

In the plastic processing industry, products may experience shrinkage, silver lines, bubbles, cracks, fiow marks, and poor transparency. Themain reason for these poor qualties is that the plastic has not been fully dried before molding. Engineering plastics such as PA, PET, PUTPU, PC, PBT, CA, and other materials with strong moisture absorption, cannot be completely dried by traditional hot air dryers due to theinfiltration of water into the plastic particles. it has been proven through practice that reducing the dew point of the drying air to below.40c whle controling the heat to blow over the surace of wet plasic particles can reduce its moisture content to below 0.02% beforemolding. The three machine integrated dehumidification and drying machine is a closed circulation system that fuly dehumidifies andheats the air, and the dry air quickly separates the moisture in the plastic particles to achieve the effect of dehumidification and drying.

Highest Rated Products

Back

Product Inquiry

Product Inquiry