Login

Contact

Description

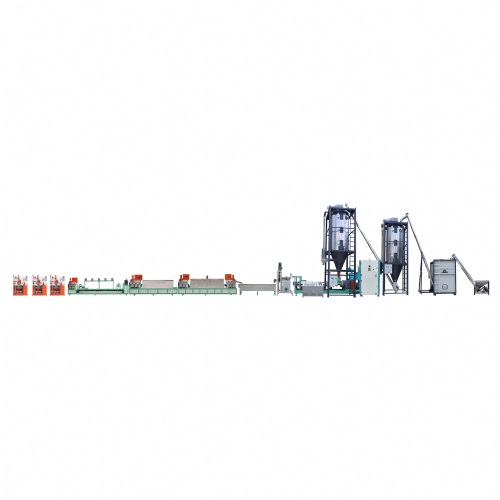

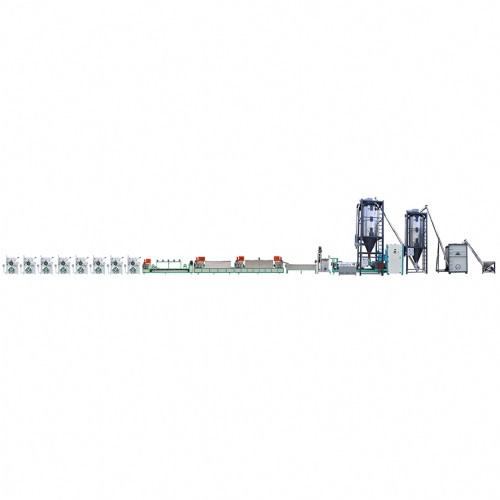

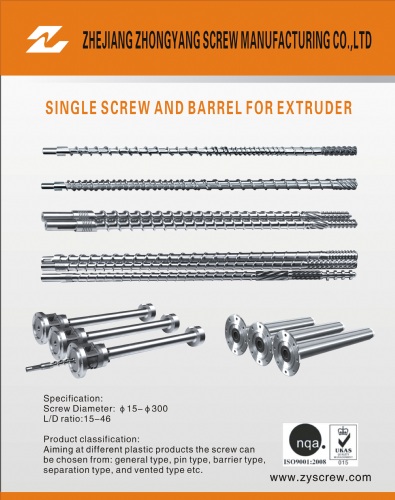

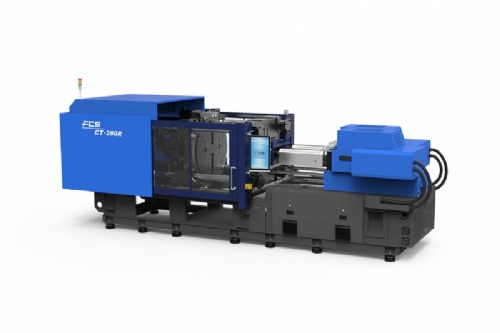

1. Extrusion system

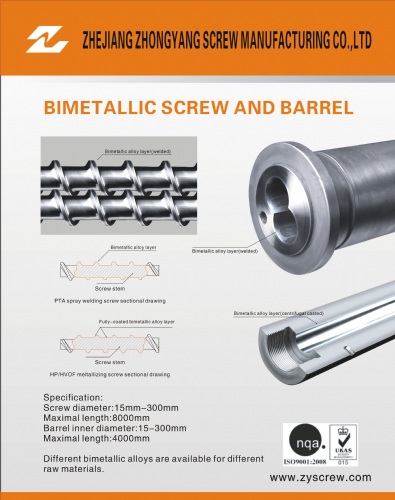

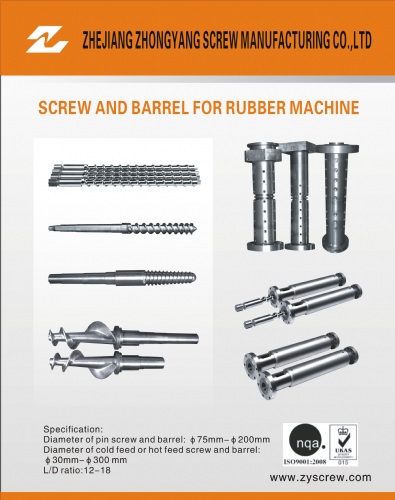

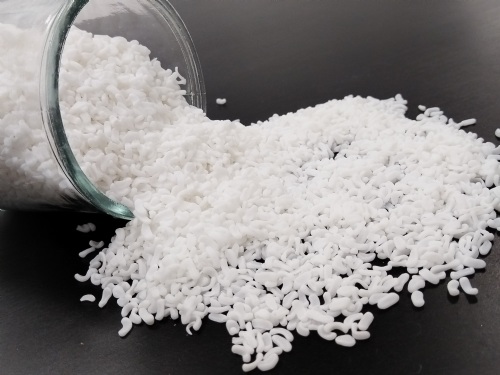

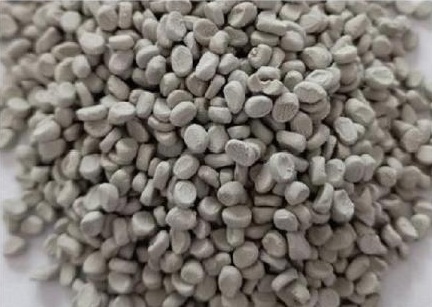

Single/twin screw extruder:

Responsible for heating and melting plastic particles and plasticizing them evenly.

The screw length-to-diameter ratio (L/D) is usually 28:1~33:1 to ensure uniform plasticization.

Heating method: electric heating + air cooling/water cooling temperature control.

Screen changer (melt filter):

Filter impurities in the melt to improve the quality of the sheet.

Manual/hydraulic automatic screen change to reduce downtime.

2. Die system

T-type hanger die (key component):

Ensure uniform distribution of the melt to avoid uneven thickness.

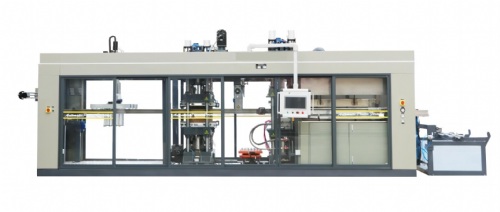

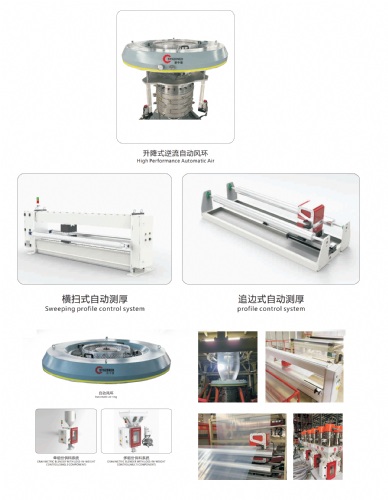

3. Calendering and shaping system

Three-roll calender:

Roller material: mirror chrome-plated steel to ensure a smooth surface of the sheet.

Adjust the roller distance (0.2mm~2mm) to control the thickness of the sheet.

4. Cooling and traction system

Cooling device: air cooling

Tractor: Use rubber rollers or silicone rollers to avoid scratching the surface of the sheet.

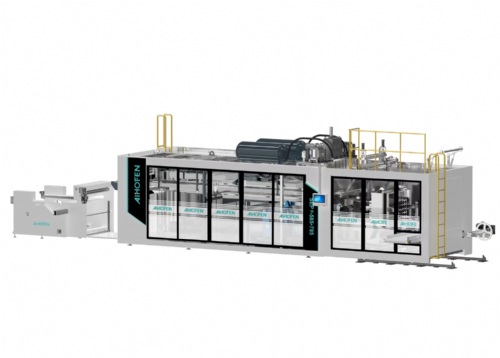

5. Winding/cutting system

Automatic winder (for film/sheet): tension control to prevent deformation of the coil.

Fixed-length cutter (for thick sheet/plate): hydraulic/pneumatic cutting, accuracy ±1mm.

6. Control system

PLC+touch screen:

Control temperature, speed, pressure and other parameters.

II. Application areas

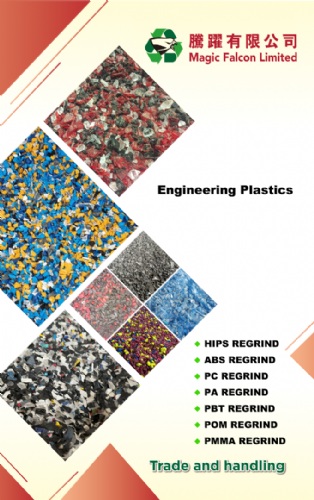

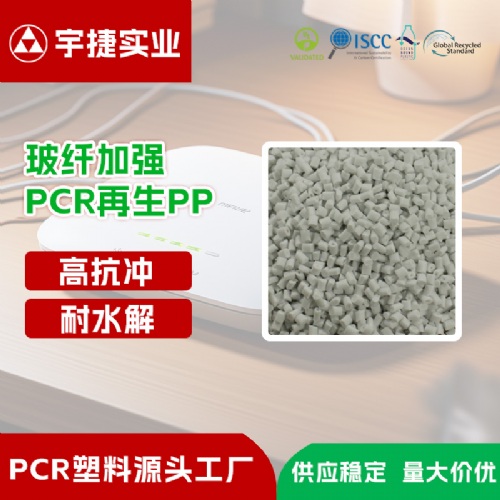

1. Food packaging

Disposable lunch boxes (PP/PS sheets)

Blister trays (PET/APET sheets)

2. Medical and electronics

Medical packaging sheets (PETG, HIPS)

Anti-static trays for electronic products (PS)

Single/twin screw extruder:

Responsible for heating and melting plastic particles and plasticizing them evenly.

The screw length-to-diameter ratio (L/D) is usually 28:1~33:1 to ensure uniform plasticization.

Heating method: electric heating + air cooling/water cooling temperature control.

Screen changer (melt filter):

Filter impurities in the melt to improve the quality of the sheet.

Manual/hydraulic automatic screen change to reduce downtime.

2. Die system

T-type hanger die (key component):

Ensure uniform distribution of the melt to avoid uneven thickness.

3. Calendering and shaping system

Three-roll calender:

Roller material: mirror chrome-plated steel to ensure a smooth surface of the sheet.

Adjust the roller distance (0.2mm~2mm) to control the thickness of the sheet.

4. Cooling and traction system

Cooling device: air cooling

Tractor: Use rubber rollers or silicone rollers to avoid scratching the surface of the sheet.

5. Winding/cutting system

Automatic winder (for film/sheet): tension control to prevent deformation of the coil.

Fixed-length cutter (for thick sheet/plate): hydraulic/pneumatic cutting, accuracy ±1mm.

6. Control system

PLC+touch screen:

Control temperature, speed, pressure and other parameters.

II. Application areas

1. Food packaging

Disposable lunch boxes (PP/PS sheets)

Blister trays (PET/APET sheets)

2. Medical and electronics

Medical packaging sheets (PETG, HIPS)

Anti-static trays for electronic products (PS)

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry