Login

Contact

Description

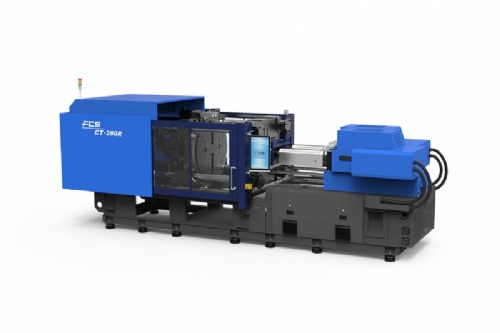

Feature:

1.Using high-performance hot air diffusion design to ensure uniform temperature distribution and improve drying efficiency

2.Electric barrel bending design, to avoid combustion caused by raw material powder accumulation at the bottom of the barre

3.Equipped with a PID controller and a 4.3-inch touchscreen to display real-time working status.

4.Designed for high energy efficiency, saving 30%-80% energy compared to ordinary models under the same working conditions.

5.Incorporates built-in process recipes for multiple common raw materials; simply select the material type, and the system automatically sets the drying temperature and air volume.

6.With an adaptive function that automatically adjusts the air volume after setting the temperature for optimal operation.

7.Includes an auto heat preservation function that activates when the machine stops feeding, saving energy, preventing over-drying, and ensuring dry materials are always ready for use.

1.Using high-performance hot air diffusion design to ensure uniform temperature distribution and improve drying efficiency

2.Electric barrel bending design, to avoid combustion caused by raw material powder accumulation at the bottom of the barre

3.Equipped with a PID controller and a 4.3-inch touchscreen to display real-time working status.

4.Designed for high energy efficiency, saving 30%-80% energy compared to ordinary models under the same working conditions.

5.Incorporates built-in process recipes for multiple common raw materials; simply select the material type, and the system automatically sets the drying temperature and air volume.

6.With an adaptive function that automatically adjusts the air volume after setting the temperature for optimal operation.

7.Includes an auto heat preservation function that activates when the machine stops feeding, saving energy, preventing over-drying, and ensuring dry materials are always ready for use.

Highest Rated Products

Back

Product Inquiry

Product Inquiry