Login

Contact

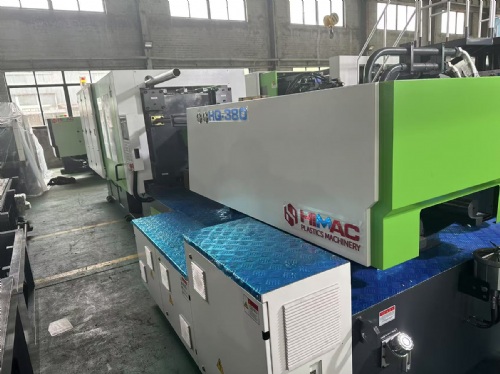

Description

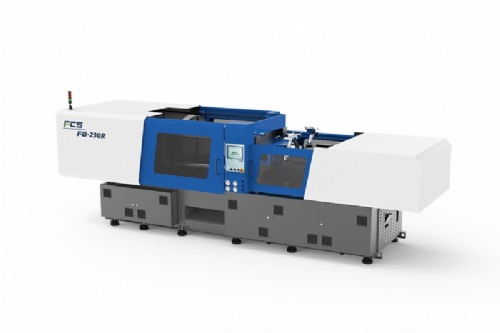

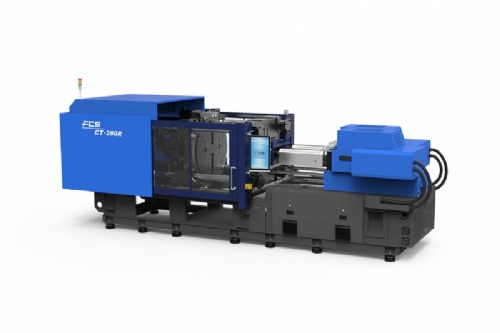

1. High injection speed, generally starting at 220 mm/s, with optional high-speed options of 300 mm/s and 550 mm/s, resulting in high efficiency.

2. High injection precision, resulting in fine product details. Six servo motors are used throughout the entire injection molding process, ensuring precise injection force control and virtually defect-free product details.

3. Energy-efficient. Our measurements show that a 150-ton machine consumes 5-6 kWh of electricity per hour, saving over 60% compared to hydraulic injection molding machines, saving over 10,000 yuan in electricity bills per month.

4. Easy maintenance. The servo motors used in pure electric vehicles simplify wiring and maintenance. Consumable parts such as the motor driver, solenoid valve, and fuses are compact and easy to replace. You can replace them yourself, reducing maintenance costs.

2. High injection precision, resulting in fine product details. Six servo motors are used throughout the entire injection molding process, ensuring precise injection force control and virtually defect-free product details.

3. Energy-efficient. Our measurements show that a 150-ton machine consumes 5-6 kWh of electricity per hour, saving over 60% compared to hydraulic injection molding machines, saving over 10,000 yuan in electricity bills per month.

4. Easy maintenance. The servo motors used in pure electric vehicles simplify wiring and maintenance. Consumable parts such as the motor driver, solenoid valve, and fuses are compact and easy to replace. You can replace them yourself, reducing maintenance costs.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry