Login

Contact

Description

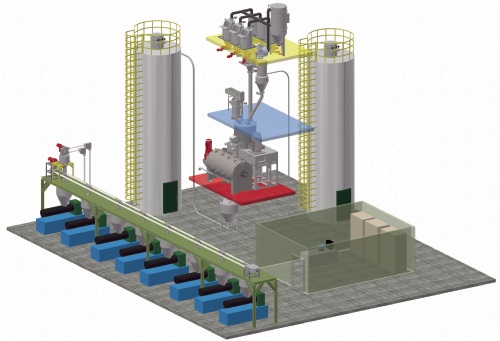

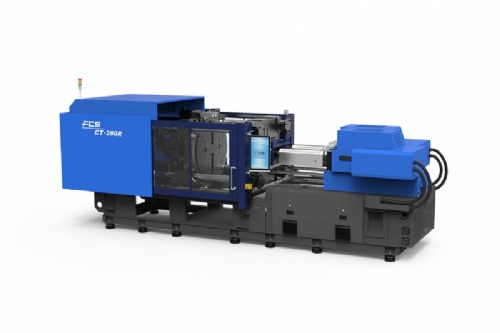

1.Energy saving, improved heat exchange rate (up to 10% improvement in heating section)

2.Extended equipment life (over 3 years for European, Japanese, American brands)

3.Stable heat conversion, increased yield rate (1% increase)

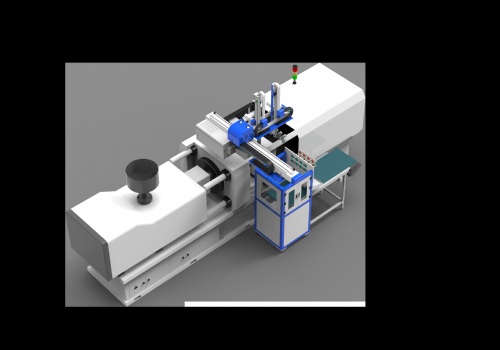

4.Faster molding cycle, fast thermal conductivity (reducing molding time by 5%)

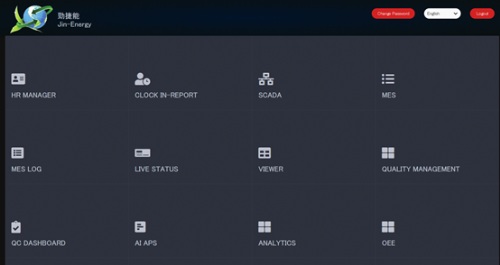

5.Automatic detection, smart monitoring, digital management

6.Reduced water usage, cost savings, environmental compliance (saving up to 50% compared to manual handling)

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry