Đăng nhập

Liên hệ

Description

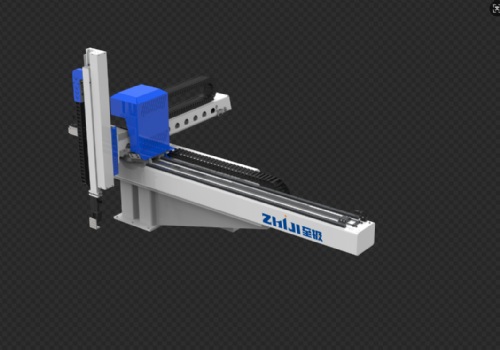

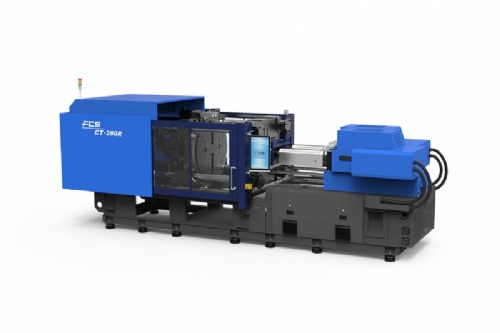

The side-entry in-mold labeling (IML) machine is an automated device used to precisely insert labels into molds during the injection molding process. It is widely applied in the production of plastic containers (such as food packaging, cosmetic caps, medical supplies, etc.). Its core function is to integrate labels directly into the product during molding, replacing traditional post-molding labeling processes. Below are its main functions and features: I. Core Functions 1.Automated Labeling Uses robotic arms or conveyor systems to accurately feed labels into the mold from the side. The molten plastic bonds with the label during injection, creating a seamless product surface.

2. High-Precision Positioning - Utilizes vision systems or sensors to detect label position, ensuring alignment accuracy (typically within ±0.1mm) and preventing misplacement or wrinkles.

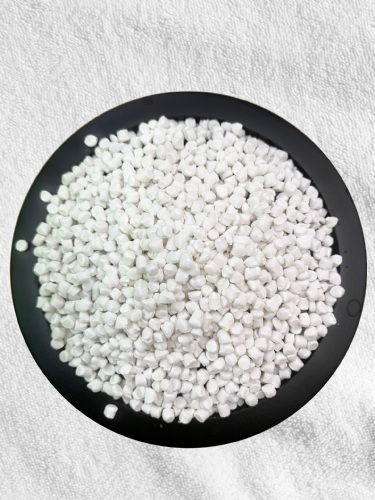

3. Multi-Label Compatibility - Handles various label materials (PP, PE, PET,paper, etc.)

2. High-Precision Positioning - Utilizes vision systems or sensors to detect label position, ensuring alignment accuracy (typically within ±0.1mm) and preventing misplacement or wrinkles.

3. Multi-Label Compatibility - Handles various label materials (PP, PE, PET,paper, etc.)

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry