Login

Contact

Description

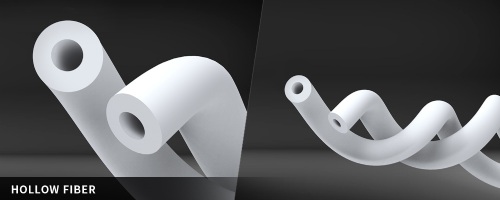

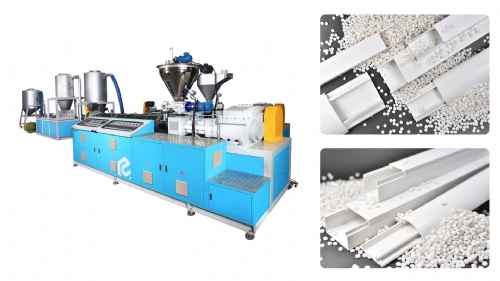

BKS Knives offers a production service of professional knives, including high-end quality die-plates and gala pelletizer blades. We offer new plates for all renowned OEM’s (BKG, MAAG, GALA, AUTOMATIK etc.) with our unique special carbide layer. The wear layer is applied by PTA welding and diffuses into the parent material of the die-plate body for our first technology. The advantage is that there are no interruptions as with the tungsten carbide segments and that no minimal layer thickness is required. The layer can be used until the last 0,1mm. Our execution and material composition have a substantially longer life time.

The second technology that BKS is proposing is the classic tungsten carbide segments brazed in the die plate ring. The advantage is that the hardness of the tungsten carbide segments is higher of the PTA for the application needed high resistance to the abrasion. Our execution and material composition have a substantially longer life.

The second technology that BKS is proposing is the classic tungsten carbide segments brazed in the die plate ring. The advantage is that the hardness of the tungsten carbide segments is higher of the PTA for the application needed high resistance to the abrasion. Our execution and material composition have a substantially longer life.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry