Login

Contact

Description

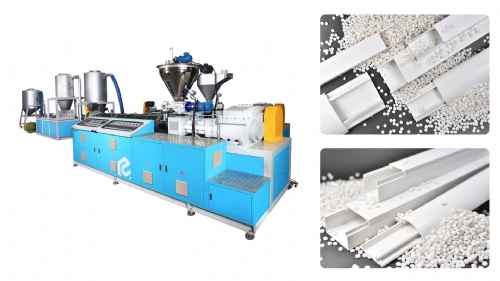

This machine is properly designed for the production of oil seal. After dividing the upper-table by upper-ejector, it can divide by pushing the mold core and close/open by pushing & rotation. Core-separation system on the upper table is suitable for precise oil-seal production.

Be capable of reducing setting times of operating conditions of same items by storaging operating conditions (20set) by touch screen monitor and prompt remedy to the breakdowns and operation is possible by preserving messages(195items) for the operations and defects.

Efficient production management is possible by computer communication because of the receiving data at the computer room with real time (option)

Be capable of reducing setting times of operating conditions of same items by storaging operating conditions (20set) by touch screen monitor and prompt remedy to the breakdowns and operation is possible by preserving messages(195items) for the operations and defects.

Efficient production management is possible by computer communication because of the receiving data at the computer room with real time (option)

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry