Login

Contact

Description

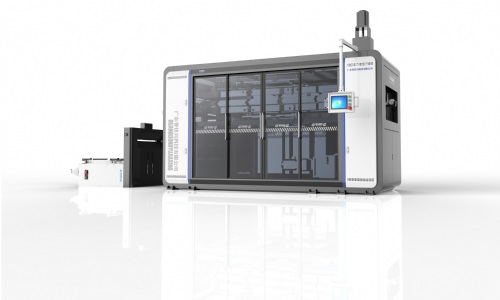

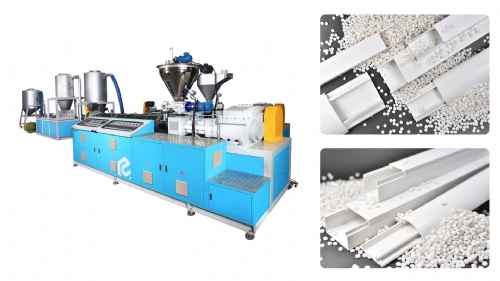

> Controlled by microprocessor, liquid-crystal display, touch button.

> Chinese and English versions are available.

> It is easy to operate andunderstand system error.

> P.l.D control adopted, keeping the mould temperature accurately (less than ±0.5°C).

> The electrical and heating equipment are separated to avoid high temperature damage to machine.

> Used high quality and high efficiency pumps, applicable to all mould temperature control requirements.

> The inside was made of stainless steel, corrosion resistance, high pressure explosion protection, constant temperature for a long time and high heat efficiency.

> Six protective measures: alarm for thermocouple open circuit, phase fault protect, pump protect, overheat protect and water shortage protect.

> Chinese and English versions are available.

> It is easy to operate andunderstand system error.

> P.l.D control adopted, keeping the mould temperature accurately (less than ±0.5°C).

> The electrical and heating equipment are separated to avoid high temperature damage to machine.

> Used high quality and high efficiency pumps, applicable to all mould temperature control requirements.

> The inside was made of stainless steel, corrosion resistance, high pressure explosion protection, constant temperature for a long time and high heat efficiency.

> Six protective measures: alarm for thermocouple open circuit, phase fault protect, pump protect, overheat protect and water shortage protect.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry