Login

Contact

Description

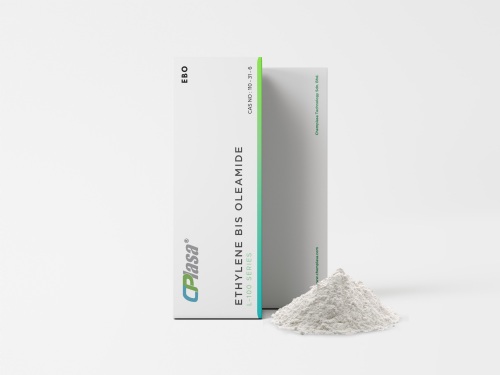

The open master batch is made up of imported British grain oleic acid and erucic acid amide. It is a kind of functional master silicon dioxide, which is developed to reduce the friction between the inner molecules of plastics during processing and to improve the opening performance of thin film products. This product can significantly reduce the adhesion of plastic products (especially plastic film) surface, can effectively improve the gloss and smoothness of the film. The surface friction coefficient of PE and PP films decreased to 0.15-0.2, and that of PE and PP films decreased to 0.06-0.1 after 2-3 days, because it contains high purity of imported oleic acid amide and erucic acid amide, so at the same time the film will have a good opening effect. Suitable for blowing film of LDPE, LLDPE, HDPE, Bopp, CPP, CPP, etc. . Improve Surface finish, transparency, tensile and impact strength.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry