Login

Contact

Description

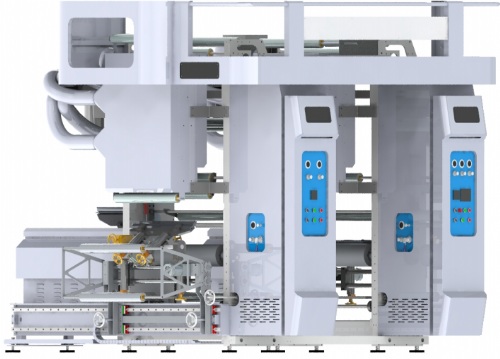

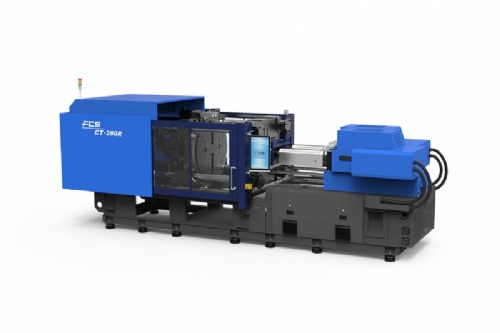

1. The machine is added with reverse printing structure: automatically change front and back side.

2. The main machine adopts servo motor automatic traction.

3. Shaftless gravure cylinder loading, which changing gravure cylinder easier and time-saving.

4. Transmission: Electronic shaft drive.

5. Unwinding and rewinding traction adopts: Servo motor automatically.

6. The rewinding are controlled by servo motor.

7. The printing press roll and the traction press roll are controlled by pneumatic components, which can also adjust the material thickness.

8. Heavy duty tool rest pneumatic back pressure mobile scraper.

9. Using infrared sealed dryer,environmental protection and power saving.

10. Unwinding adopts: ultrasonic rectify left and right tracking system.

11. Independent switch for each printing drive system.

12. The max diameter of rewinding and unwinding material is 650mm.

13. Rewinding and unwinding adopts high speed non-stop automatically receiving material device, especially for double layer plastic film, both available for material inside and outside corona.

2. The main machine adopts servo motor automatic traction.

3. Shaftless gravure cylinder loading, which changing gravure cylinder easier and time-saving.

4. Transmission: Electronic shaft drive.

5. Unwinding and rewinding traction adopts: Servo motor automatically.

6. The rewinding are controlled by servo motor.

7. The printing press roll and the traction press roll are controlled by pneumatic components, which can also adjust the material thickness.

8. Heavy duty tool rest pneumatic back pressure mobile scraper.

9. Using infrared sealed dryer,environmental protection and power saving.

10. Unwinding adopts: ultrasonic rectify left and right tracking system.

11. Independent switch for each printing drive system.

12. The max diameter of rewinding and unwinding material is 650mm.

13. Rewinding and unwinding adopts high speed non-stop automatically receiving material device, especially for double layer plastic film, both available for material inside and outside corona.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry