Đăng nhập

Liên hệ

Description

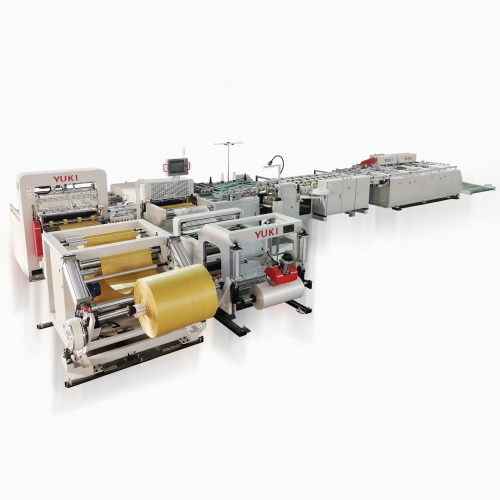

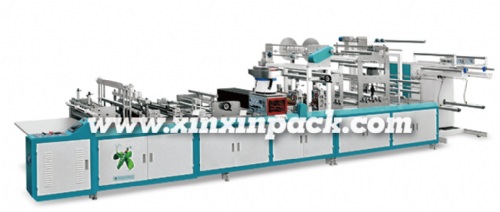

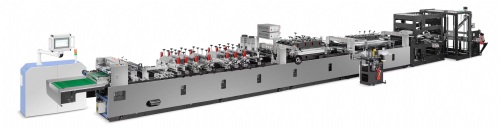

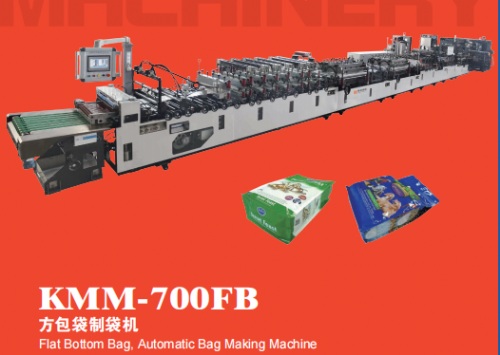

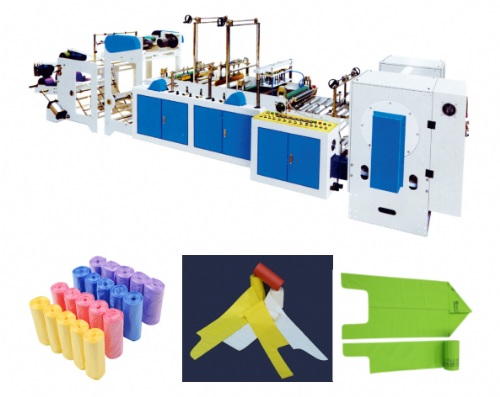

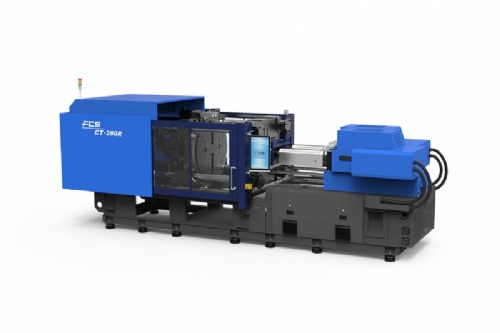

This machine handles non-laminated/laminated bags, single/double-sided BOPP bags, non-wovens, paper-plastic bags, and three-layer laminated bags. One-touch hot/cold cutter switch via touch screen (1-minute switch): hot for non-laminated (servo cutting, double mouth twisting); cold for laminated (no change, neat cuts).

Non-laminated woven bags have dual openings unsealed to reduce inner film insertion blockage and boost stability. Fabric/film delivery uses EPC auto deviation correction, controlling positions for uniform lining.

Fabric delivery has magnetic powder brake and tension systems, reducing non-contact outer bag damage. EPC sync correction, dual servo inner film control, precise seal alignment, cutting/lining synchronized.

Imported Japanese PLC and servo, Mitsubishi control, 10-inch touch screen (data functions). Auto alignment, positioning, folding, sewing, counting, collection. Easy, one-person operation; usable alone as cutter/sewer.

Non-laminated woven bags have dual openings unsealed to reduce inner film insertion blockage and boost stability. Fabric/film delivery uses EPC auto deviation correction, controlling positions for uniform lining.

Fabric delivery has magnetic powder brake and tension systems, reducing non-contact outer bag damage. EPC sync correction, dual servo inner film control, precise seal alignment, cutting/lining synchronized.

Imported Japanese PLC and servo, Mitsubishi control, 10-inch touch screen (data functions). Auto alignment, positioning, folding, sewing, counting, collection. Easy, one-person operation; usable alone as cutter/sewer.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry