Login

Contact

Description

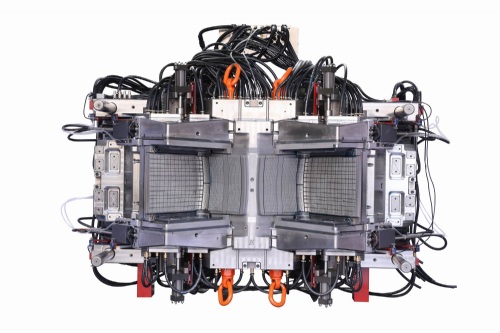

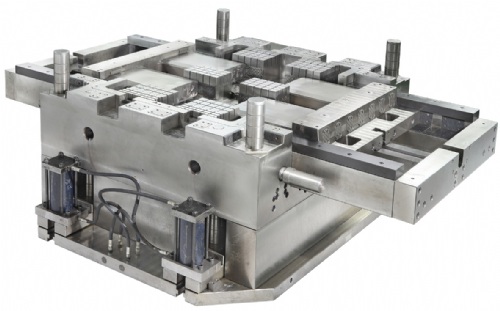

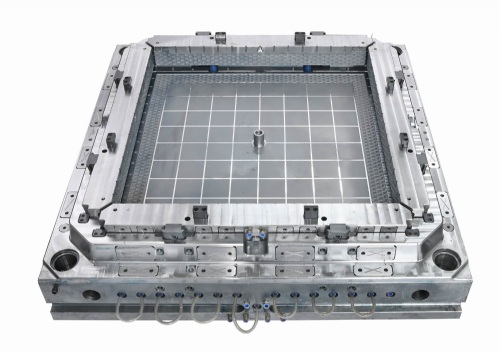

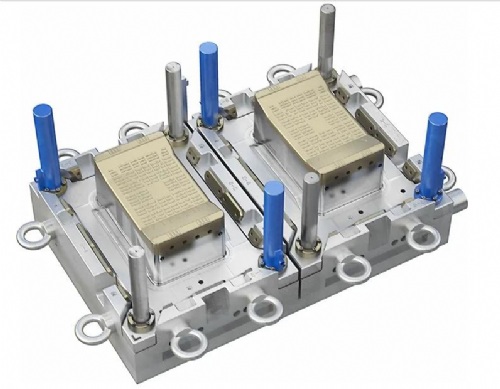

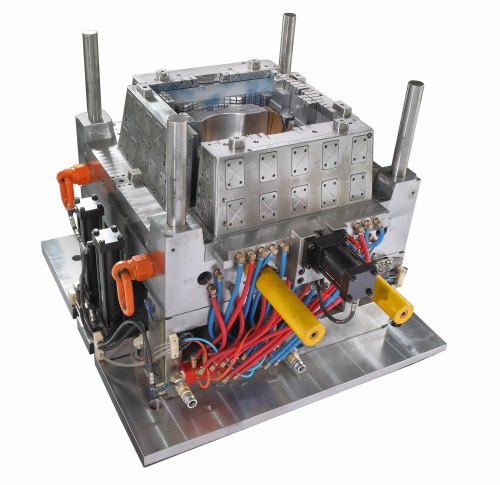

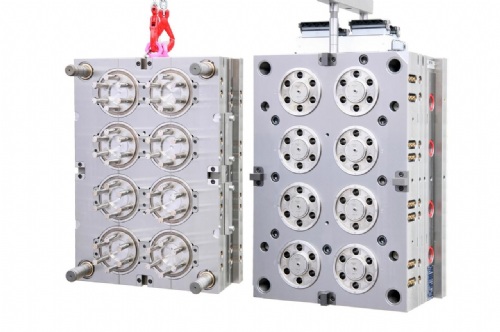

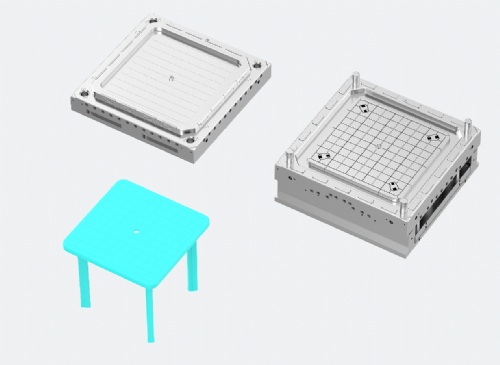

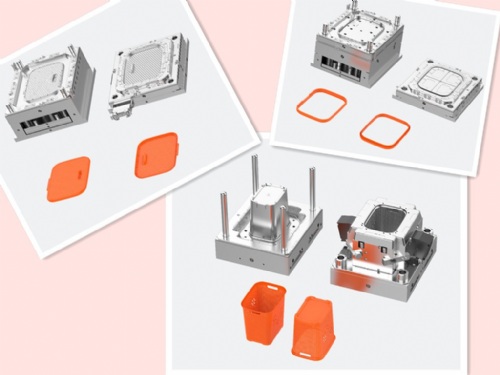

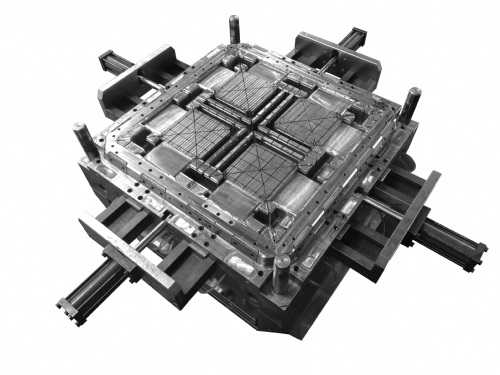

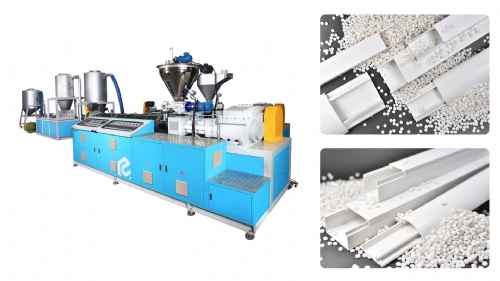

Jnmould has produced many different types of plastic basket mould, such as shopping basket mould, laundry basket mould, storage basket mould, etc. cooling and rapid prototyping are the key requirements of this kind of mould, we have accumulated some experience in many years of production.

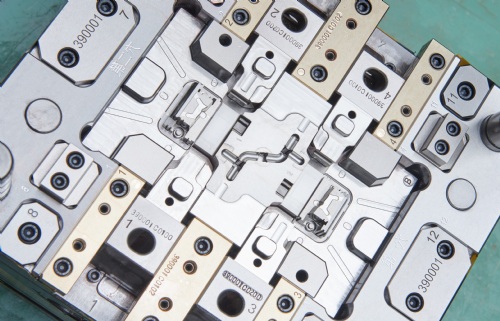

1. Beryllium copper is used at the top of the core part of the plastic basket mould to increase the cooling effect, improve the quality of the basket and the production efficiency of the basket mould.

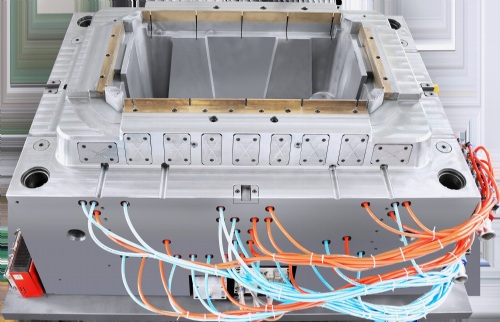

2. The plastic basket mould has many bumping holes. When designing the basket mould, the reasonable parting surface and R angle should be considered to avoid the phenomenon of bumping through holes and running edges. At the same time, the reasonable cooling channel are designed on both sides of the core and cavity to avoid the issue of welding line.

3. In terms of material selection of plastic basket mould, we generally recommend 2738.

1. Beryllium copper is used at the top of the core part of the plastic basket mould to increase the cooling effect, improve the quality of the basket and the production efficiency of the basket mould.

2. The plastic basket mould has many bumping holes. When designing the basket mould, the reasonable parting surface and R angle should be considered to avoid the phenomenon of bumping through holes and running edges. At the same time, the reasonable cooling channel are designed on both sides of the core and cavity to avoid the issue of welding line.

3. In terms of material selection of plastic basket mould, we generally recommend 2738.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry