Login

Contact

Description

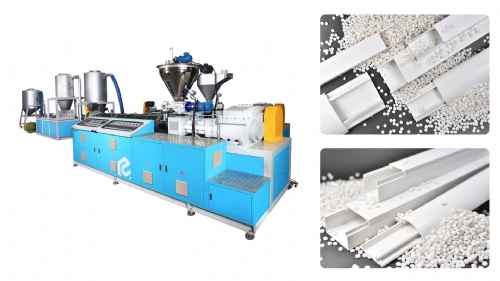

Adopting a horizontal structure and three rows of inverted blades to ensure mixing to every corner of the cylinder, the material is constantly flipped during operation, and the wood powder, plastic, and color powder additives are stirred evenly in a short period of time;

The blade is made of stainless steel at one time, and the gap with the cylinder is adjustable;

High efficiency, energy saving and consumption reduction, the installed power is only 1/4 of the power of the traditional mixer (the power of the traditional high mixer is 90~132KW);

Adopting a unique humanized design concept in the equipment structure, it facilitates cleaning, color changing, reduces material loss, and reduces labor costs;

The electronic control system is designed to focus on an operation panel, and each link adopts closed-loop control, which can ensure that the equipment runs automatically without manual operation one by one.

The blade is made of stainless steel at one time, and the gap with the cylinder is adjustable;

High efficiency, energy saving and consumption reduction, the installed power is only 1/4 of the power of the traditional mixer (the power of the traditional high mixer is 90~132KW);

Adopting a unique humanized design concept in the equipment structure, it facilitates cleaning, color changing, reduces material loss, and reduces labor costs;

The electronic control system is designed to focus on an operation panel, and each link adopts closed-loop control, which can ensure that the equipment runs automatically without manual operation one by one.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry