Login

Contact

Description

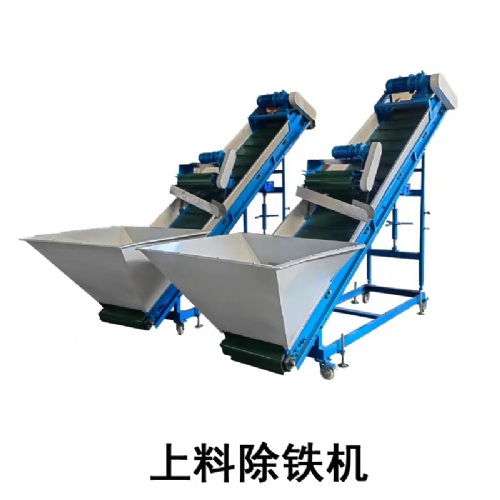

The belt conveyor with iron removal function is a highly practical conveying equipment.

This type of conveyor is equipped with an iron removal device. As the materials are transported on the belt, the iron removal device can effectively detect and remove ferrous metals mixed in the materials. This helps to prevent damage to downstream processing equipment and improve the purity of the conveyed materials.

The iron removal function is usually achieved through magnetic separation. Powerful magnets are installed on the conveyor to attract and hold ferrous metals, which can then be removed manually or automatically.

The belt conveyor with iron removal function offers several advantages. Firstly, it simplifies the material handling process by integrating iron removal and conveying in one unit. Secondly, it reduces the risk of equipment damage and downtime caused by ferrous metal contaminants. Thirdly, it improves the quality of the final product by ensuring that the materials are free from iron impurities.

In summary, the belt conveyor with iron removal function is an efficient and reliable solution for material handling and iron removal in various industries.

This type of conveyor is equipped with an iron removal device. As the materials are transported on the belt, the iron removal device can effectively detect and remove ferrous metals mixed in the materials. This helps to prevent damage to downstream processing equipment and improve the purity of the conveyed materials.

The iron removal function is usually achieved through magnetic separation. Powerful magnets are installed on the conveyor to attract and hold ferrous metals, which can then be removed manually or automatically.

The belt conveyor with iron removal function offers several advantages. Firstly, it simplifies the material handling process by integrating iron removal and conveying in one unit. Secondly, it reduces the risk of equipment damage and downtime caused by ferrous metal contaminants. Thirdly, it improves the quality of the final product by ensuring that the materials are free from iron impurities.

In summary, the belt conveyor with iron removal function is an efficient and reliable solution for material handling and iron removal in various industries.

Highest Rated Products

Back

Product Inquiry

Product Inquiry