Login

Contact

Description

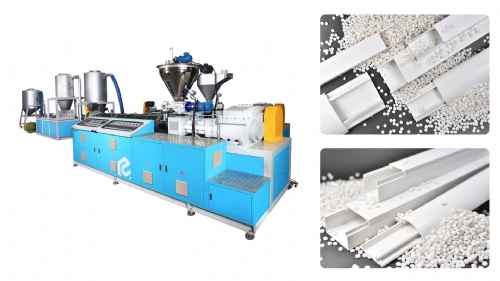

The plastic dehydrator is a device designed to remove moisture from plastic materials.

It is widely used in the plastic processing industry. The main function of a plastic dehydrator is to separate water from plastic pellets or flakes, improving the quality and processing performance of the plastic.

Plastic dehydrators typically consist of a rotating drum or screw conveyor, a heating system, and a ventilation system. The plastic material is fed into the dehydrator, where it is heated and agitated to evaporate the moisture. The ventilation system then removes the moist air, leaving the dried plastic.

There are several advantages of using a plastic dehydrator. Firstly, it reduces the moisture content of the plastic, preventing problems such as bubbles, voids, and degradation during processing. Secondly, it improves the flowability and handling properties of the plastic, making it easier to process and mold. Thirdly, it can increase the productivity and efficiency of the plastic processing line by reducing drying time and energy consumption.

In addition, plastic dehydrators can be customized to meet the specific needs of different plastic materials and processing requirements. They come in various sizes and capacities, ranging from small laboratory models to large industrial-scale units.

Overall, the plastic dehydrator is an important piece of equipment for the plastic processing industry, helping to ensure the quality and performance of plastic products.

It is widely used in the plastic processing industry. The main function of a plastic dehydrator is to separate water from plastic pellets or flakes, improving the quality and processing performance of the plastic.

Plastic dehydrators typically consist of a rotating drum or screw conveyor, a heating system, and a ventilation system. The plastic material is fed into the dehydrator, where it is heated and agitated to evaporate the moisture. The ventilation system then removes the moist air, leaving the dried plastic.

There are several advantages of using a plastic dehydrator. Firstly, it reduces the moisture content of the plastic, preventing problems such as bubbles, voids, and degradation during processing. Secondly, it improves the flowability and handling properties of the plastic, making it easier to process and mold. Thirdly, it can increase the productivity and efficiency of the plastic processing line by reducing drying time and energy consumption.

In addition, plastic dehydrators can be customized to meet the specific needs of different plastic materials and processing requirements. They come in various sizes and capacities, ranging from small laboratory models to large industrial-scale units.

Overall, the plastic dehydrator is an important piece of equipment for the plastic processing industry, helping to ensure the quality and performance of plastic products.

Highest Rated Products

Back

Product Inquiry

Product Inquiry