Login

Contact

Description

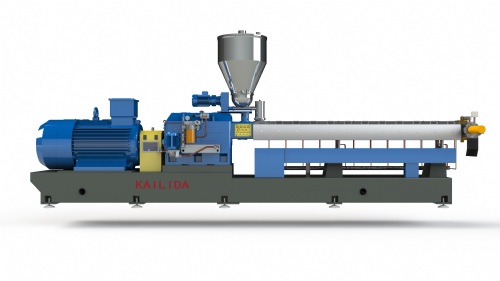

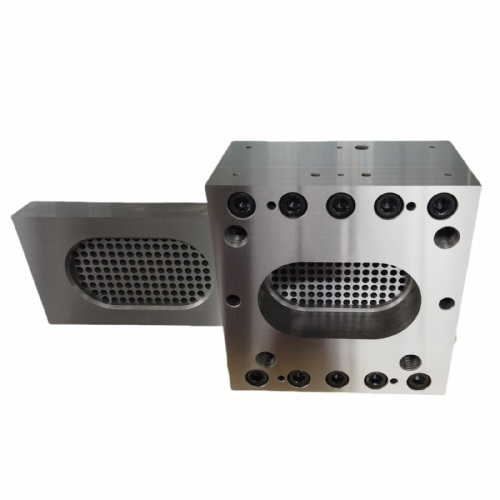

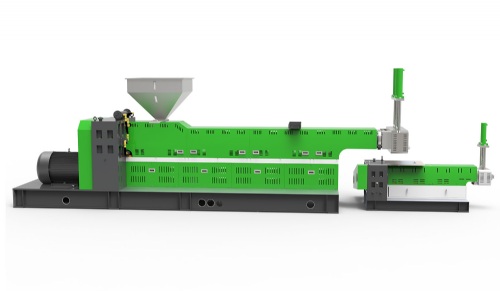

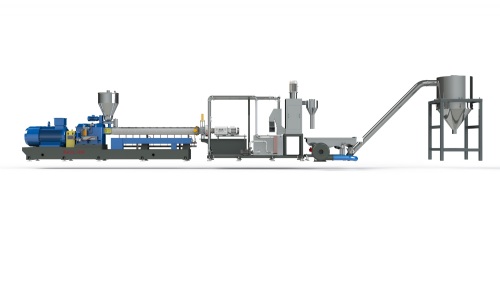

The FL - Air-Cooling Hot-Cutting Pelletizing System has several advantages in the pelletizing process:

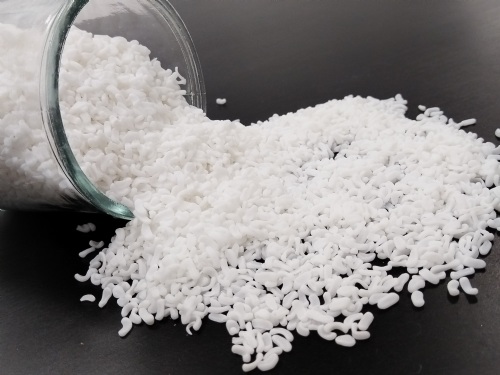

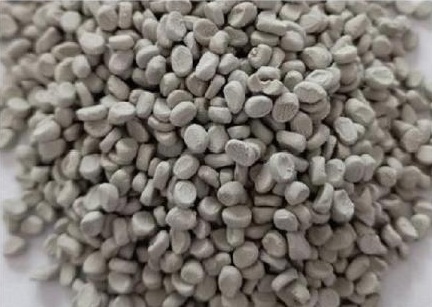

‧ Avoiding material contact with water:

During the pelletizing process of air-cooled die-face hot-cutting, the material does not come into contact with water. This helps maintain the purity and consistency of the material, reducing the possibility of impurities and contamination.

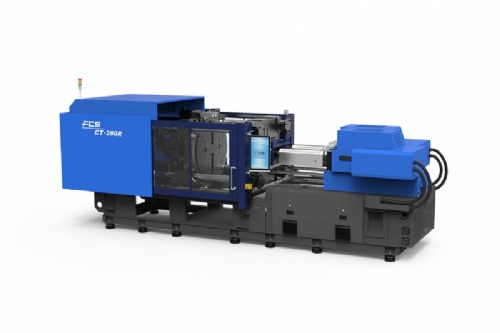

‧Simple equipment and convenient operation:

The equipment used for air-cooled die-face hot-cutting technology is relatively simple, and the operation is also convenient. This reduces the difficulty and complexity of operation and improves production efficiency.

‧Easy to clean and maintain:

The air-cooled die-face hot-cutting pelletizer has undergone technological innovations in the connection structure between the machine head and the barrel, such as using a half-lock flange to replace the original connecting flange.This not only significantly reduces labor intensity, shortens cleaning time, and reduces the

‧ Avoiding material contact with water:

During the pelletizing process of air-cooled die-face hot-cutting, the material does not come into contact with water. This helps maintain the purity and consistency of the material, reducing the possibility of impurities and contamination.

‧Simple equipment and convenient operation:

The equipment used for air-cooled die-face hot-cutting technology is relatively simple, and the operation is also convenient. This reduces the difficulty and complexity of operation and improves production efficiency.

‧Easy to clean and maintain:

The air-cooled die-face hot-cutting pelletizer has undergone technological innovations in the connection structure between the machine head and the barrel, such as using a half-lock flange to replace the original connecting flange.This not only significantly reduces labor intensity, shortens cleaning time, and reduces the

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry