Đăng nhập

Liên hệ

Description

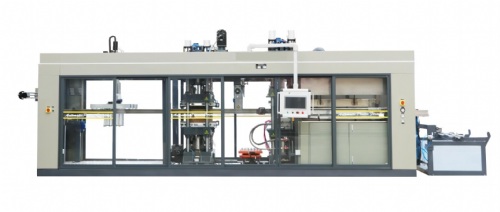

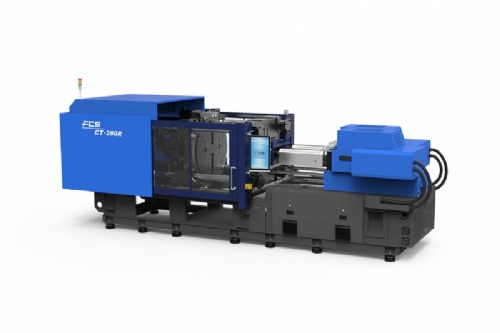

A plastic cup thermoforming machine is an automated production line designed to manufacture disposable or reusable plastic cups through a high-efficiency thermoforming process. The machine heats a plastic sheet, molds it into cup shapes, trims excess material, and outputs finished products ready for packaging. It is widely used in the food, beverage, and packaging industries due to its fast production speed, low cost, and flexibility in product design.

Main Components

1. Unwinding Rack (Feeding System)

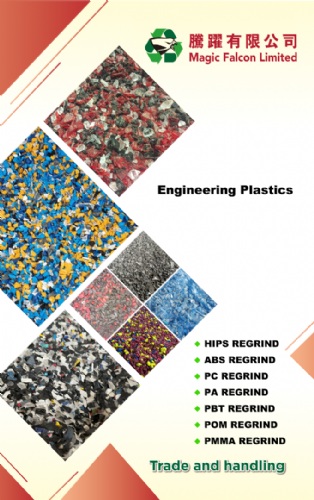

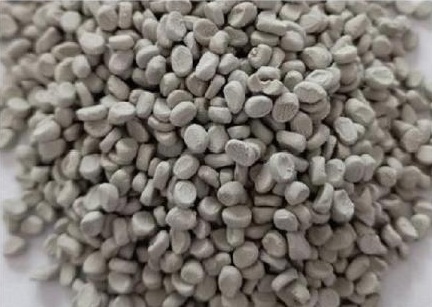

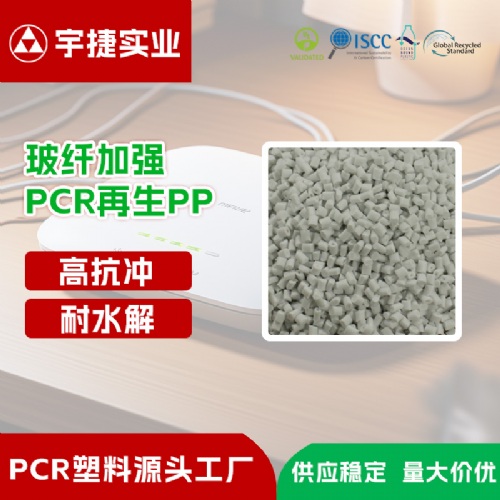

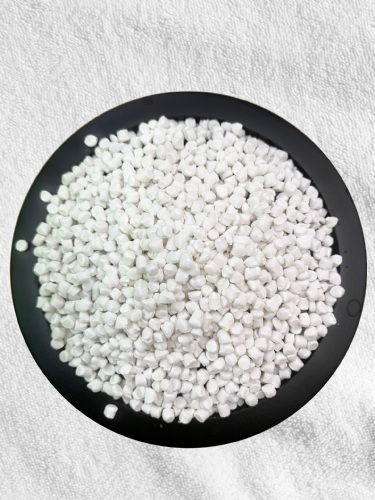

? Holds and feeds the plastic roll (PP, PS, PET, or biodegradable PLA) into the machine.

? Ensures smooth and tension-controlled material delivery for consistent forming.

2. Heating Zone

? Uses infrared or ceramic heaters to soften the plastic sheet to a precise forming temperature (typically 150–200°C).

? Temperature is adjustable to suit different materials and thicknesses.

3. Forming Zone

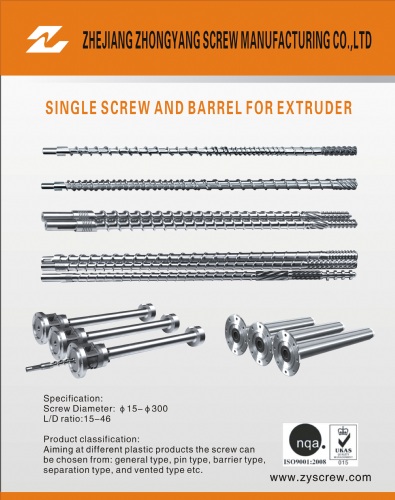

? The heated plastic sheet is pressed into a mold by pneumatic cylinders or servo motors, creating the cup shape.

? Cooling & cutting are integrated into the mold:

■ Cooling: The mold has built-in cooling channels (water or air) to solidify the plastic quickly.

■ Cutting: The mold includes trimming blades activated by cylinder pressure or servo-driven mechanisms for precise separation.

4. Rewinding System

? Collects the leftover plastic web (trimmed edges) for recycling, minimizing material waste.

5. Electrical Control Cabinet

? Houses the PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for automated operation.

? Adjusts parameters like temperature, forming pressure, and production speed.

Key Features & Advantages

‧ High Efficiency: Produces thousands of cups per hour with consistent quality.

‧ Precision Forming: Servo motors or pneumatic cylinders ensure accurate mold pressure and clean cuts.

‧ Customizable: Supports various cup sizes, shapes, and materials (including eco-friendly options like PLA).

‧ Low Maintenance: Simple mechanical structure with durable molds.

Applications

‧ Disposable cups for coffee, tea, soft drinks, and desserts.

‧ Reusable containers for dairy products (yogurt, pudding).

‧ Custom-branded cups for promotions or events.

Main Components

1. Unwinding Rack (Feeding System)

? Holds and feeds the plastic roll (PP, PS, PET, or biodegradable PLA) into the machine.

? Ensures smooth and tension-controlled material delivery for consistent forming.

2. Heating Zone

? Uses infrared or ceramic heaters to soften the plastic sheet to a precise forming temperature (typically 150–200°C).

? Temperature is adjustable to suit different materials and thicknesses.

3. Forming Zone

? The heated plastic sheet is pressed into a mold by pneumatic cylinders or servo motors, creating the cup shape.

? Cooling & cutting are integrated into the mold:

■ Cooling: The mold has built-in cooling channels (water or air) to solidify the plastic quickly.

■ Cutting: The mold includes trimming blades activated by cylinder pressure or servo-driven mechanisms for precise separation.

4. Rewinding System

? Collects the leftover plastic web (trimmed edges) for recycling, minimizing material waste.

5. Electrical Control Cabinet

? Houses the PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for automated operation.

? Adjusts parameters like temperature, forming pressure, and production speed.

Key Features & Advantages

‧ High Efficiency: Produces thousands of cups per hour with consistent quality.

‧ Precision Forming: Servo motors or pneumatic cylinders ensure accurate mold pressure and clean cuts.

‧ Customizable: Supports various cup sizes, shapes, and materials (including eco-friendly options like PLA).

‧ Low Maintenance: Simple mechanical structure with durable molds.

Applications

‧ Disposable cups for coffee, tea, soft drinks, and desserts.

‧ Reusable containers for dairy products (yogurt, pudding).

‧ Custom-branded cups for promotions or events.

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry