Login

Contact

Description

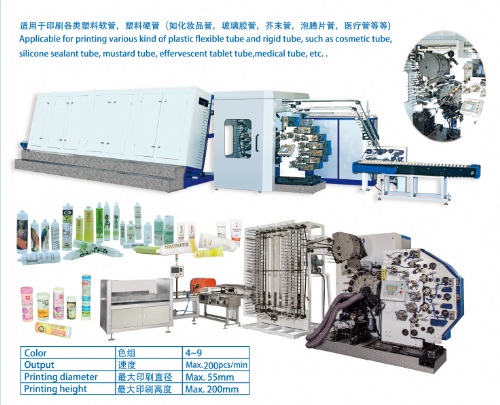

Flexographic printing machine uses a fluid ink with strong fluidity, the ink is transmitted to the graphic part of the printing plate by the ink roller and the mesh ink roller, and then the printing pressure is applied by the press roller to transfer the ink on the printing plate to the substrate, and finally the printing process is completed by the dry surface. Flexographic printing machine mainly consists of 4 parts, namely, unwinding feeding parts, printing parts, drying parts and rewinding receiving parts. In the modern flexographic press, there are generally tension control, edge control, registration control, printing observation and other measurement and control devices and mechanical condition monitoring and fault diagnosis system.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry