Đăng nhập

Liên hệ

Description

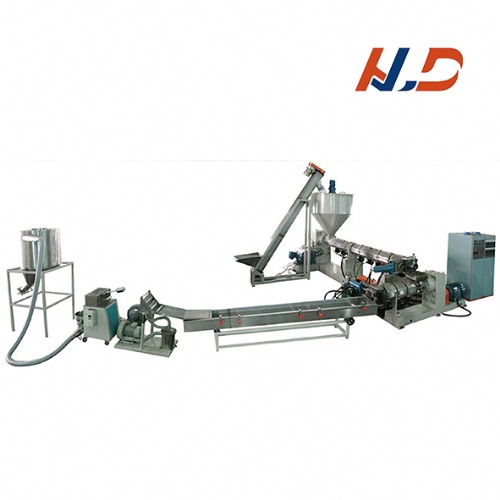

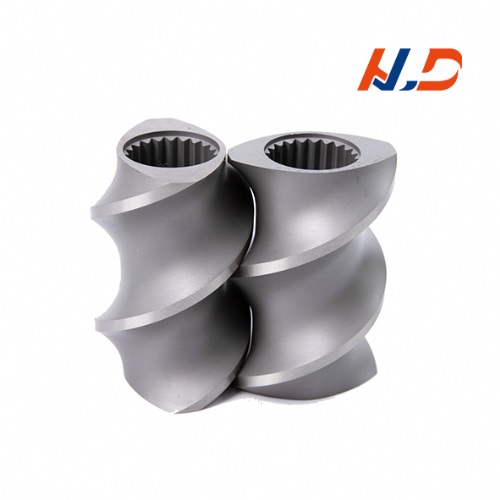

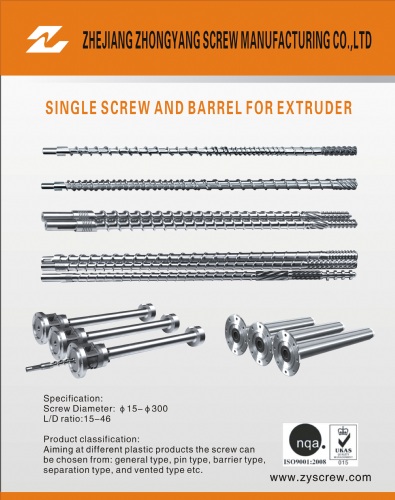

The first section is a high-speed co-rotating twin-screw mixer, and the second section is a low-speed single-screw extruder. The two are arranged in a T-shape to form a two-stage composite unit.

Principle characteristics and uses:

1. The advantages of co-rotating twin screws and single screws are combined and complemented. Twin screws force conveying, efficient plasticizing mixing and shear dispersion, no head back pressure reflux, avoiding high shear overheating; single screw high pressure extrusion, but low speed and low shear, also avoids overheating contradictions

2. The combination of twin screws and single screws decomposes the process functions, increases independent operating variables, and is conducive to the step-by-step optimization of each process; improves efficiency and production capacity.

3. Widely used in various heat-sensitive material systems and large-capacity devolatilization operations, such as: PV, XLPE, halogen-free flame-retardant cable materials, shieldin

Principle characteristics and uses:

1. The advantages of co-rotating twin screws and single screws are combined and complemented. Twin screws force conveying, efficient plasticizing mixing and shear dispersion, no head back pressure reflux, avoiding high shear overheating; single screw high pressure extrusion, but low speed and low shear, also avoids overheating contradictions

2. The combination of twin screws and single screws decomposes the process functions, increases independent operating variables, and is conducive to the step-by-step optimization of each process; improves efficiency and production capacity.

3. Widely used in various heat-sensitive material systems and large-capacity devolatilization operations, such as: PV, XLPE, halogen-free flame-retardant cable materials, shieldin

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry