Đăng nhập

Liên hệ

Description

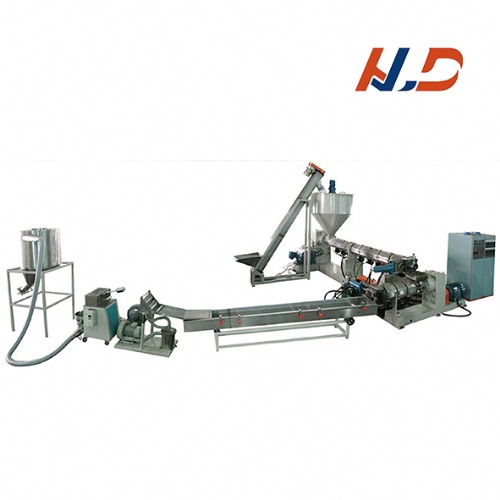

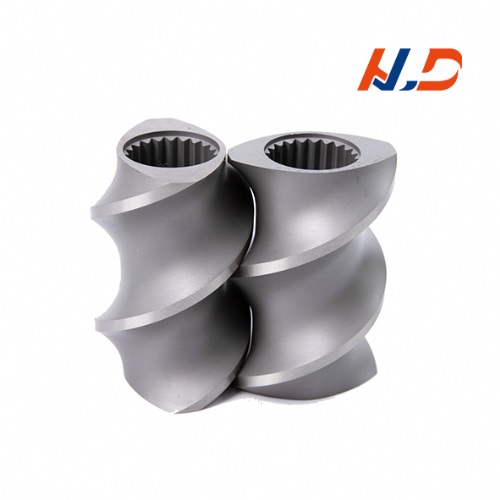

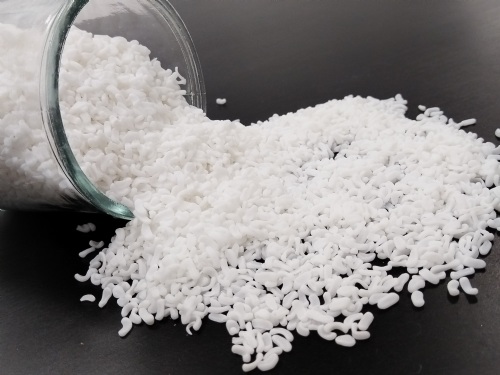

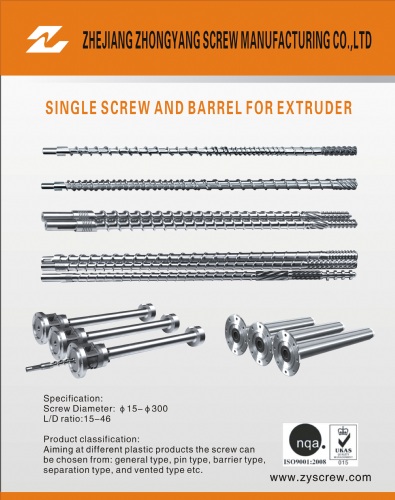

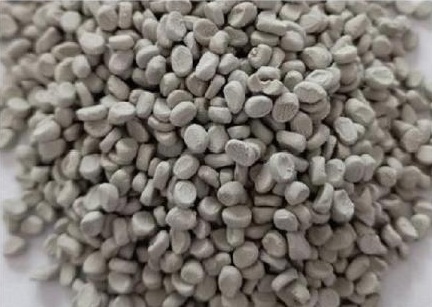

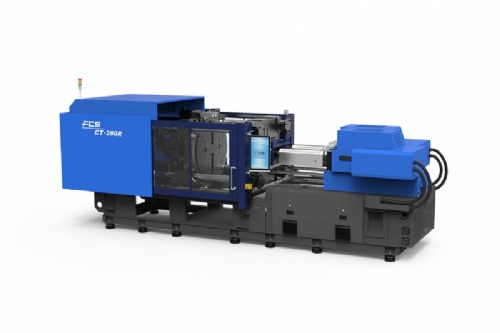

The new crystal-free drying PET sheet production line integrates a variety of twin-screw production process formula systems. The equipment has a compact structure, low energy consumption, uniform output plasticization, good sheet flexibility, good transparency, convenient equipment operation, stable extrusion, good mechanical properties, impact strength is 3~5 times that of other films, good folding resistance, oil resistance, fat resistance, dilute acid resistance, high transparency, can block ultraviolet rays, good gloss, non-toxic, odorless, good hygiene and safety, and can be directly used for food packaging.

Product application:

1. Vacuum blister forming field: catering food packaging, toy boxes, pencil boxes, gift boxes and tools, fruit hardware and other packaging;

2. Antistatic field application: electronic parts packaging, permanent conductive sheets, permanent antistatic sheets, permanent semi-conductive sheets and other packaging;

3. Blister, folding box, packaging, printin

Product application:

1. Vacuum blister forming field: catering food packaging, toy boxes, pencil boxes, gift boxes and tools, fruit hardware and other packaging;

2. Antistatic field application: electronic parts packaging, permanent conductive sheets, permanent antistatic sheets, permanent semi-conductive sheets and other packaging;

3. Blister, folding box, packaging, printin

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry