Login

Contact

Description

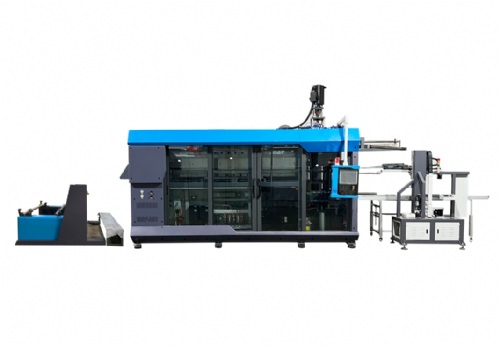

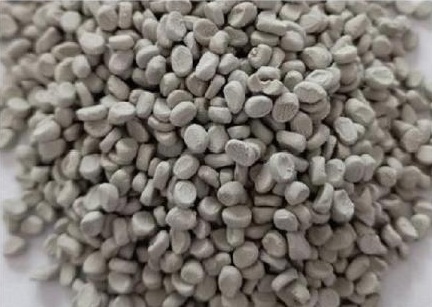

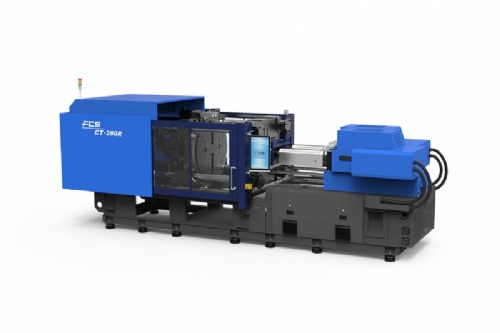

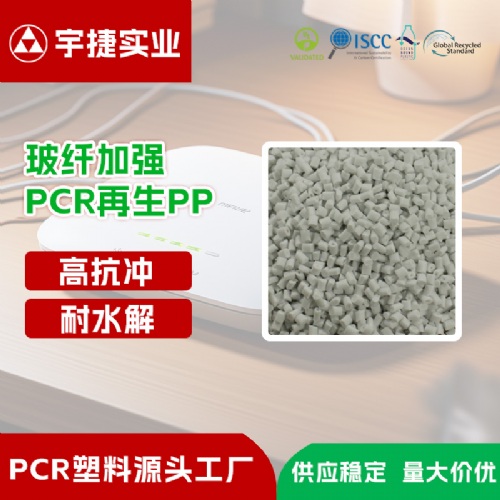

1.This machine has four fully automatic stations of heating forming punching cutting stacking counting, which can adapt to materials such as PLA, PS, PET, PP, PVS, ABS, etc.

2.This machine is widely used and has strong versatility. The positive and negative pressure forming machine has a fast speed, with a maximum speed of 2 seconds per mold.

3.Servo stretching is suitable for products with a height exceeding 50mm, which can effectively avoid the problem of thin walls after material stretching,

4.Equipped with an intelligent temperature control system, it heats up quickly, consumes less power, and saves at least10% electricity compared to traditional temperature control systems.

5.Quick mold change, replacing molds from the front of the machine, saving time and effort.

6.Remote module for easy after-sales maintenance and problem detection

2.This machine is widely used and has strong versatility. The positive and negative pressure forming machine has a fast speed, with a maximum speed of 2 seconds per mold.

3.Servo stretching is suitable for products with a height exceeding 50mm, which can effectively avoid the problem of thin walls after material stretching,

4.Equipped with an intelligent temperature control system, it heats up quickly, consumes less power, and saves at least10% electricity compared to traditional temperature control systems.

5.Quick mold change, replacing molds from the front of the machine, saving time and effort.

6.Remote module for easy after-sales maintenance and problem detection

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry