Login

Contact

Description

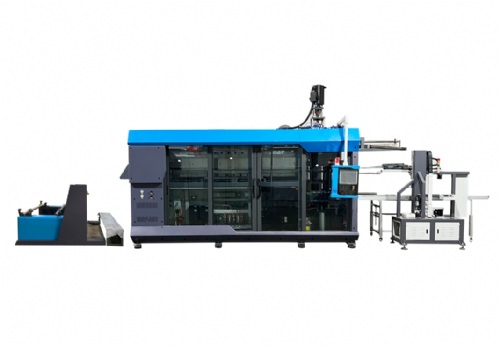

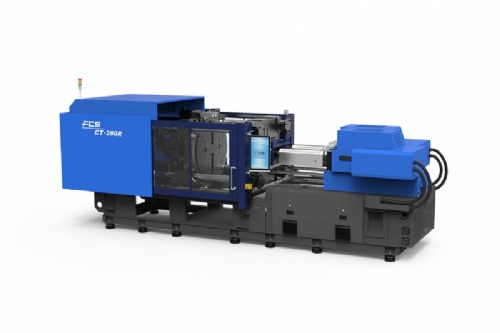

The titling mold cup machine uses molds and compressed air to form, which can achieve more precise control over the thickness and shape of the cup wall, reduce deformation and unevenness, and ensure more consistent size and quality of the product.

At the same time, the production speed is fast and the efficiency is high. It integrates molding, turning, demoulding and other processes, reducing intermediate pauses and manual intervention, thereby significantly improving production efficiency and being suitable for mass production.

Because the titling mold cup machine reduces friction during the flipping and demoulding process, causing less wear and tear, the mold generally has a longer service life and lower maintenance costs.

In summary, the flip molding cup machine has more advantages than the normal cup making machine in producing large-scale, high-quality, high-precision cup products

At the same time, the production speed is fast and the efficiency is high. It integrates molding, turning, demoulding and other processes, reducing intermediate pauses and manual intervention, thereby significantly improving production efficiency and being suitable for mass production.

Because the titling mold cup machine reduces friction during the flipping and demoulding process, causing less wear and tear, the mold generally has a longer service life and lower maintenance costs.

In summary, the flip molding cup machine has more advantages than the normal cup making machine in producing large-scale, high-quality, high-precision cup products

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry