Login

Contact

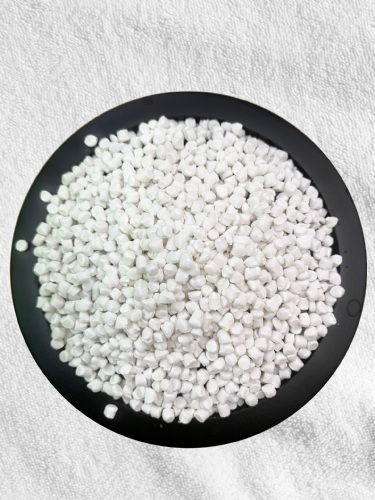

Description

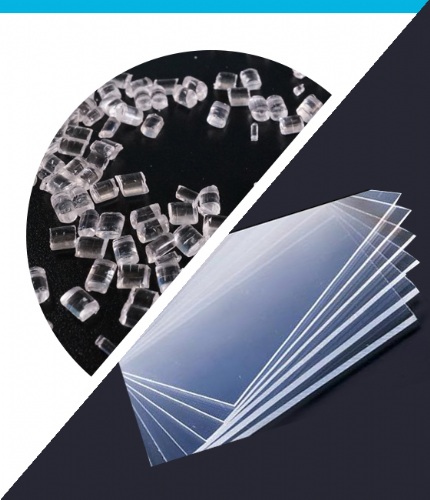

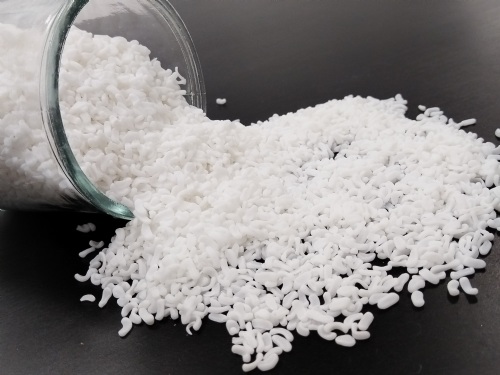

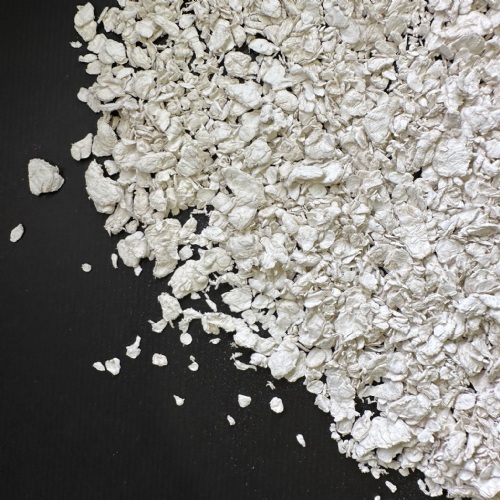

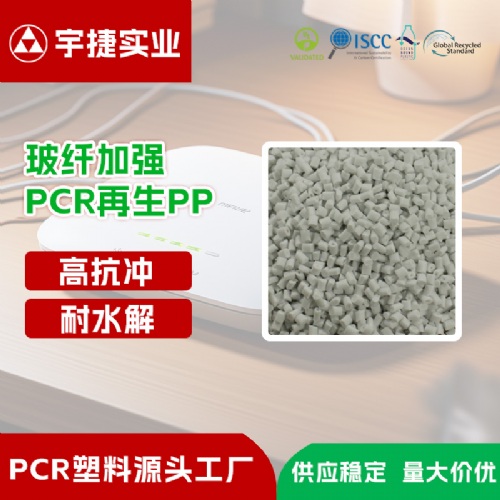

ACR is an acrylic copolymer with a core-shell structure. Its "core" is generally a crosslinked acrylic monomer polymer with a low glass transition temperature (such as PBA), and the "shell" layer is Acrylic polymers with high glass transition temperature.

PVC pure resin is easy to decompose, poor fluidity, low impact strength and poor weathering resistance, so it is necessary to add processing aid to improve its processibility.

It functions well in PVC products, which can increase the impact strength by several times and can improve processibility without reducing heat resistance property.

Intrinsic viscosity 5-7 ml/g

Fineness (0.246mm) ?98.0 % past

Moisture ?1.5 %

PVC pure resin is easy to decompose, poor fluidity, low impact strength and poor weathering resistance, so it is necessary to add processing aid to improve its processibility.

It functions well in PVC products, which can increase the impact strength by several times and can improve processibility without reducing heat resistance property.

Intrinsic viscosity 5-7 ml/g

Fineness (0.246mm) ?98.0 % past

Moisture ?1.5 %

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry