Login

Contact

Description

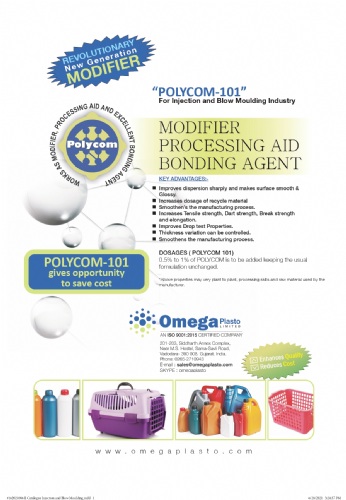

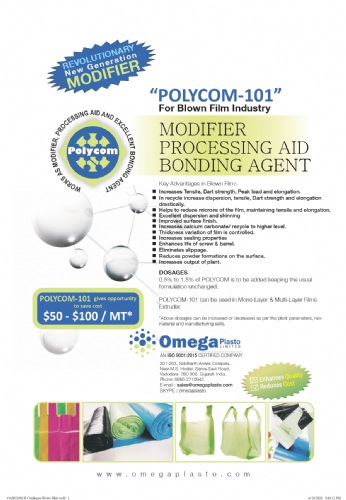

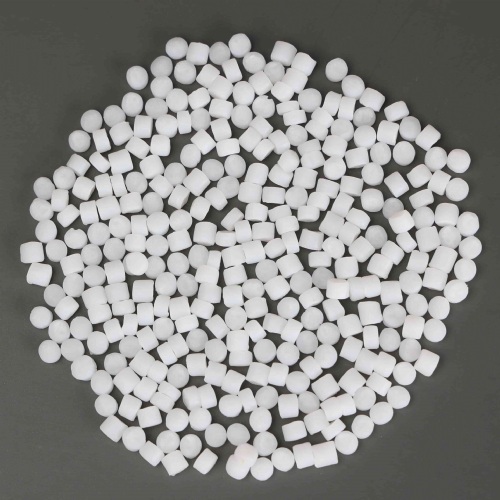

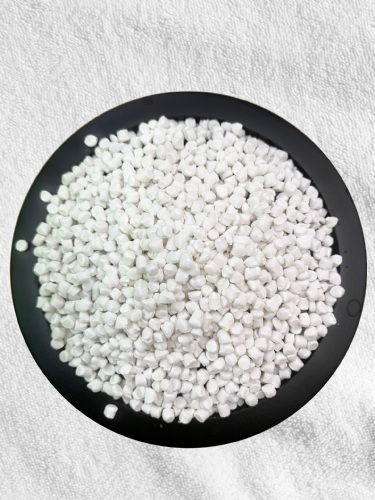

POLYCOM – 101 MODIFIER, PROCESSING AID AND BONDING AGENT FOR INJECTION & BLOW MOULDING APPLICATIONS

Key Advantages:

‧ Improves dispersion sharply and makes surface smooth & Glossy.

‧ Increases dosage of recycle material

‧ Smoothens the manufacturing process.

‧ Increases Tensile strength, Dart strength, Break strength and elongation.

‧ Improves Drop test Properties.

‧ Thickness variation can be controlled.

‧ Smoothens the manufacturing process

Dosage:

0.5% to 1 % of POLYCOM-101 is to be added keeping the usual formulation unchanged.

*Above properties may vary from plant to plant, processing skills and raw material used by the manufacturer.

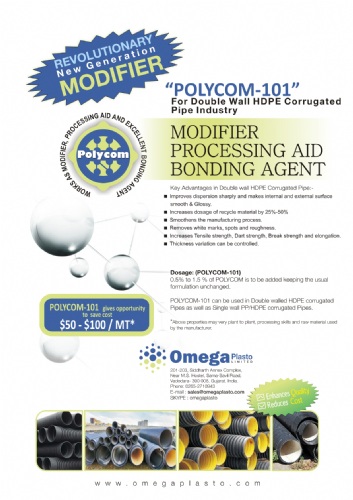

Key Advantages:

‧ Improves dispersion sharply and makes surface smooth & Glossy.

‧ Increases dosage of recycle material

‧ Smoothens the manufacturing process.

‧ Increases Tensile strength, Dart strength, Break strength and elongation.

‧ Improves Drop test Properties.

‧ Thickness variation can be controlled.

‧ Smoothens the manufacturing process

Dosage:

0.5% to 1 % of POLYCOM-101 is to be added keeping the usual formulation unchanged.

*Above properties may vary from plant to plant, processing skills and raw material used by the manufacturer.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry