Login

Contact

Description

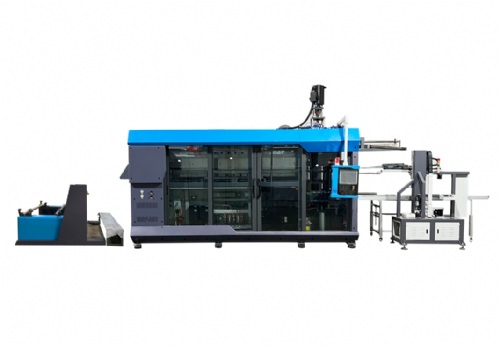

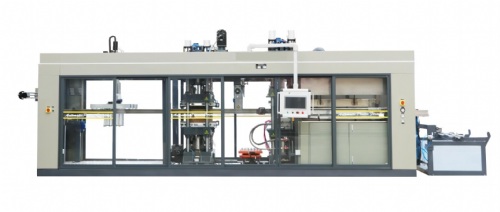

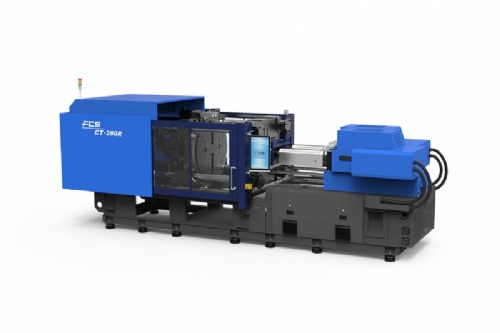

1. Mechanical, pneumatic and electrical combination, all working actions are controlled by PLC. Touch screen makes the operation convenient and easy.

2. Pressure And/Or Vacuum forming.

3. Up and down mold forming method.

4. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5. Upper & lower heater, three sections heating

6. Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won’t be effected by outer voltage.

7. Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

8. Data memorization function can store 120 set of running data.

9. Stacking type: downward stacking/Robot Stacking.

10. Feeding width can be synchronously or independently adjusted in electrical way.

11. Oven will automatically push-out when the sheet is over heated, Air pressure not enough.

12. Automatic lubrication system.

13. Quick mold change system, Auto roll sheet loading, reduce the working load.

2. Pressure And/Or Vacuum forming.

3. Up and down mold forming method.

4. Servo motor feeding, feeding length can be step-less adjusted. High speed and accurate.

5. Upper & lower heater, three sections heating

6. Heater with intellectual temperature control system, automatic supply the heating individual heater control. Fast heating(3 min from 0-400 degree), it won’t be effected by outer voltage.

7. Forming and cutting unit mold open and close controlled by servo motor, products automatically count.

8. Data memorization function can store 120 set of running data.

9. Stacking type: downward stacking/Robot Stacking.

10. Feeding width can be synchronously or independently adjusted in electrical way.

11. Oven will automatically push-out when the sheet is over heated, Air pressure not enough.

12. Automatic lubrication system.

13. Quick mold change system, Auto roll sheet loading, reduce the working load.

Related Products

You may also like

Highest Rated Products

Back

Product Inquiry

Product Inquiry